Galvanizing: The right choice for the construction industry

Galvanizing is invaluable for the construction and infrastructure sector, offering enhanced durability, corrosion resistance, and cost savings. We explain hot dip galvanizing’s role in the construction industry, and what makes it the preferred choice of coating for steel used in construction.

What types of fabrication can be galvanized?

Hot dip galvanizing is an effective coating method for many types of steel fabrication. Some examples in construction include:

- Structural steel beams and columns

- Fasteners and fixings (with the use of spin galvanizing)

- Grating, handrails, and guardrails

- Fencing, poles, and support structures

- Bridges and infrastructure components

Why hot dip galvanizing for construction?

Extended corrosion protection

Construction projects often involve outdoor or semi-exposed environments, such as bridges or industrial plants. Therefore, they are at higher risk to atmospheric attack, which is especially true for projects near coastal areas with higher salt content.

Galvanizing creates a continuous zinc coating that reaches all surfaces both inside and outside, and fully covers corners, welds, and complex structures. Unlike surface-level coatings, this ensures a much more reliable level of protection.

Hot dip galvanized steel also provides cathodic protection, meaning the zinc sacrifices itself to protect the steel, even if the surface is scratched or damaged. This scientifically backed process means that galvanizing is a reliable coating method for construction fabrications.

Long-term durability

Designers, builders, and end users all expect buildings and infrastructure to last a long time with minimal upkeep. Increased time spent on maintenance heavily impacts both financial costs of recoating or refabrication, and on downtime lost in carrying out this work.

The reaction between the steel and zinc during the galvanizing process creates a metallurgical bond, forming a protective coating that is much more durable than surface-level coatings such as paint or plating, and can even self-heal small areas of mechanical damage through its self-sacrificial properties. The bond provides a reliable, scientifically-backed method of protecting steel fabrications against corrosion, proven over decades in real world conditions. The process also reliably coats all internal and external surfaces, ensuring there are no areas left without zinc protection.

Hot dip galvanized coatings can last 60+ years in many environments, greatly reducing the maintenance cycles and associated costs affecting uncoated steel. This is especially important for large-scale projects such as bridges, towers, or elevated structures that are difficult and expensive to maintain.

Sustainability

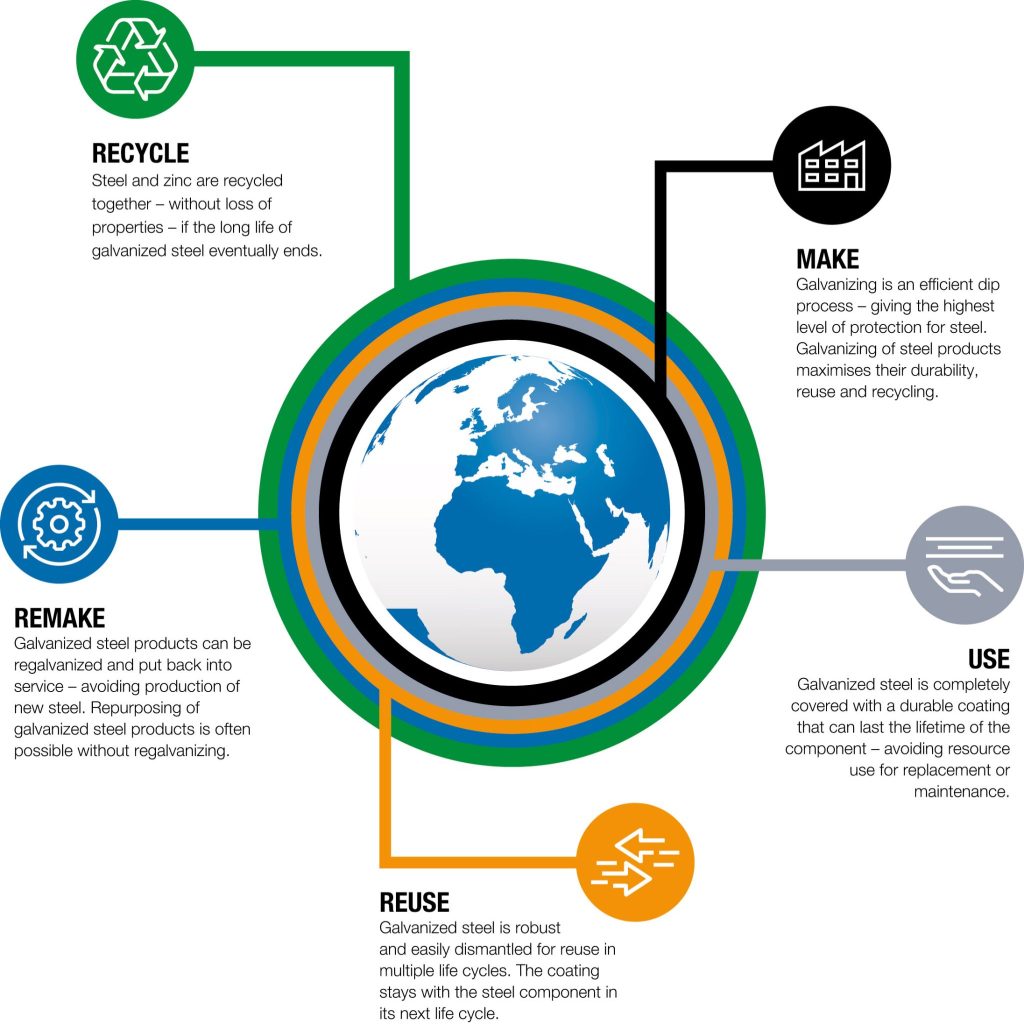

Galvanized steel supports and contributes to the principles of a circular economy.

The extended lifespan of the steel fabrications reduces resources used to remake and replace or repair and maintain the component. Additionally, the steel is robust and maintains its coating so can be readily dismantled and reused for future projects.

At the end of the coating’s lifespan (60+ years), the steel can be re-galvanized, again reducing the resources required for production of new steel. Finally, galvanized steel is fully recyclable; when it is time to dissemble to the fabrication, the steel and zinc can be fully recycled together without loss of properties.

At Joseph Ash Galvanizing, we’re also committed to protecting the environment throughout the galvanizing process itself. For example, we support waste minimisation through the recycling of process consumables such as flux solutions and the recovery of zinc from the waste stream, and we work hard at minimising energy usage. We also operate within a framework of an Environmental Management System based on internationally recognised standards.

It’s real-world proven

Galvanizing has been used and trusted for almost two centuries, with galvanized steel being a reliably used product for all kinds of fabrications used around us daily.

Joseph Ash Galvanizing has been providing galvanizing services since 1857 – longer than any other UK galvanizing company – so we have had a lot of time to perfect our craft.

Where to galvanize construction steel

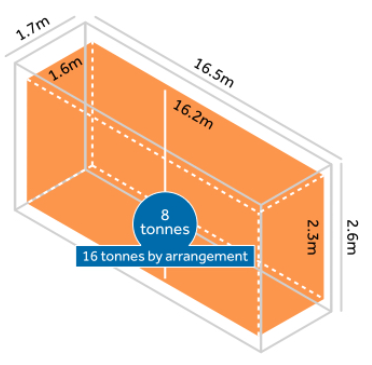

Joseph Ash Chesterfield is home to our largest galvanizing bath, able to double dip steel up to 18 metres long. We also have a spin galvanizing facility at Joseph Ash Telford, able to protect small steel items that may be crucial for construction such as brackets and fastenings.

Our Chesterfield site is also the first, and only, galvanizing company in the UK to be awarded Fit for Nuclear status, meeting the high standards required for projects within the nuclear industry.

- Extended corrosion protection for steel fabrications ✔️

- Double dip capacity of 18m length ✔️

- Collection and delivery options ✔️

- Sustainable solution ✔️