Is the galvanizing process sustainable?

Joseph Ash Galvanizing has a keen sense of responsibility for the world around it, not only when it comes to quality of work, but also sustainability and the environment.

Our team works hard to protect the environment, through an ever-growing list of recycling activities with processes supported by an Environmental and Sustainability Policy.

For example, we support waste minimisation through the recycling of process consumables such as flux solutions and the recovery of zinc from the waste stream, and we work hard at minimising energy usage. We also operate within an Environmental Management System based on internationally recognised standards.

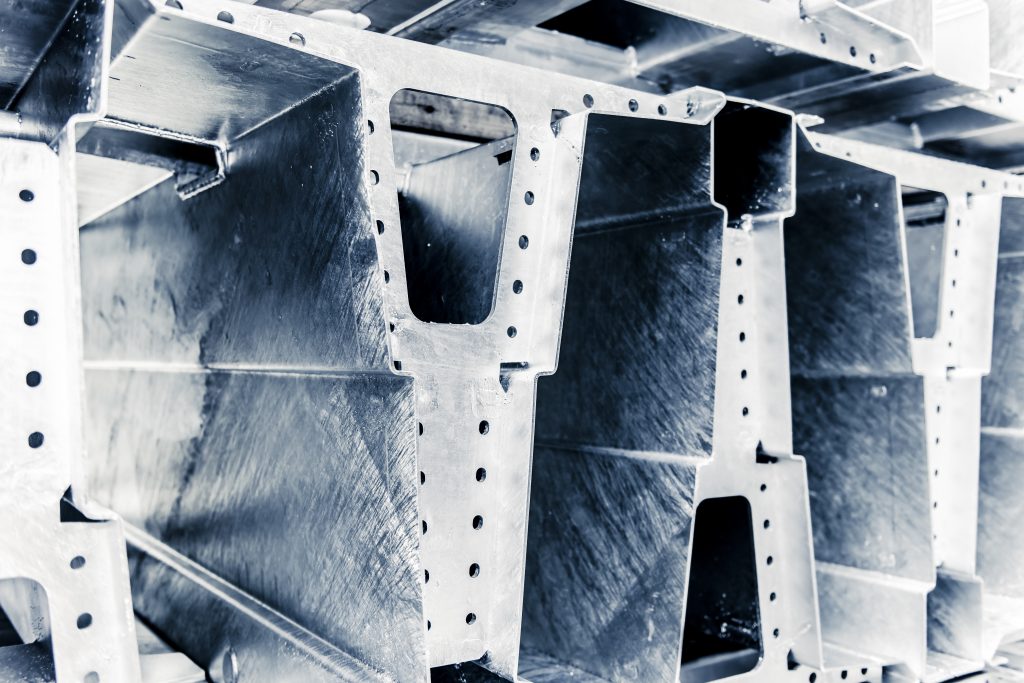

Finally, we take pride in the long life and environmental credentials of galvanizing when combined into steel building products, which have been proven to offer substantially lower lifelong environmental impact than other building materials.

Read more about the sustainable benefits of hot dip galvanizing and our environmental and sustainable practices in an article titled ‘Reinventing the steel‘.

You can also read our blog post “Is galvanizing sustainable?” for more information.

Sustainable galvanizing near you

- We’ll collect and deliver your steel to our site ✔️

- Comprehensive technical support, guidance and assistance at every stage ✔️

- Hot dip galvanized to BS EN ISO 1461 standards ✔️

- Part of a circular economy ✔️