Plant focus: Spotlight on Bilston

The Joseph Ash Group has nine plants across the UK, from Medway in the South to Hull in the North. We’re putting the spotlight on our Bilston to share its history and capabilities.

About Joseph Ash Bilston

Joseph Ash Bilston is located on Springvale Park, where esteemed business Bilston Steelworks was developed in the 1700s, making steel for over 200 years.

Joseph Ash Bilston is home to the productive semi-automatic facility in the UK. It also opened its energy-efficient office block in 2022.

Finally, the team at the plant has been working hard on environmental initiatives for several years, installing equipment such as solar panels, solar storage systems, an air source heat pump, radiant ceiling grid panels, and 60 double-glazed windows using the latest energy efficient glass.

UK’s deepest galvanizing bath

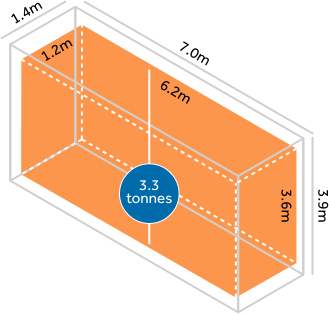

Joseph Ash Bilston is home to the deepest galvanizing bath in the UK, with a total depth of 3.9m and a dipping capacity of 3.6m. These dimensions help make it the ideal place to dip long fabrications such as motorway guardrails, fencing products and industrial flooring.

With its collection and delivery service, the plant services clients from areas including Warwickshire, Worcestershire, West Midlands, Gloucestershire, Oxfordshire, Northamptonshire, Leicestershire, Staffordshire, Shropshire, and Herefordshire. Work can also be transported work to other Joseph Ash plants using our own fleet of trucks.

More than galvanizing

As well as galvanizing, Joseph Ash Bilston can provide shot blasting (through an external shot-blasting subcontractor). Bilston can also offer powder coating, duplex coatings, and spin galvanizing via the other Joseph Ash Galvanizing plants.

We also offer a range of additional services:

- Collection and delivery: We can collect and deliver your steel to and from our site, saving you time.

- Full technical support: Ensures customers receive guidance and assistance at every stage, guaranteeing a smooth galvanizing process.

- Packing and bundling: We can bundle, pack, and label your steel per your requirements and can accommodate if you need items delivered to the end user or prepared for export or containerisation.

Extended opening hours and quick turnaround times

Joseph Ash Bilston has extended opening hours to assist customers wishing to drop work off early and collect it late. Get in touch with us to find out more.

We can also provide a quick turnaround (overnight and within 24 hours) by prior arrangement.

Quality and accreditations

We’re proud to hold numerous accreditations and certifications for our work and the standards we galvanize to.

All our hot dip galvanizing is to BS EN ISO 1461 specifications. These standards help ensure a consistent, reliable coating is achieved from the process, with guidance on minimum specifications for coating thickness. We also hold the NQA ISO 9001:2015 accreditation for Quality Management Systems, ISO 14001:2015 for Environmental Management Systems, and ISO 45001 for Occupational Health and Safety Management Systems.

Whatever your requirements, at Joseph Ash Galvanizing are here to help. Contact our Bilston team today for more information.