Plant focus: Spotlight on Chesterfield

The Joseph Ash Group is home to 9 UK galvanizing plants, ranging from Medway in the South to Hull in the North. Here, we shine the spotlight on our Joseph Ash Chesterfield site, one of our galvanizing plant in the Midlands and home to our longest galvanizing bath.

About Joseph Ash Chesterfield

Joseph Ash Chesterfield is located just half a mile off the M1 Junction 29 at Holmewood Industrial Estate, making it conveniently location for those arranging their own transport. Wee can also offer collection and delivery across the Midlands with a daily milk run service within a 50-mile radius of the plant.

Joseph Ash Chesterfield is home to our largest galvanizing bath, at over 16 metres in length and a double-dip capacity of 18m length, able to galvanize even the largest of structural steel fabrications such as support columns.

History of galvanizing in Chesterfield

Joseph Ash Chesterfield is based in Derbyshire, a region of England historically tied to the growth and development of the steel and iron industry in the 19th century.

With so much metalwork and engineering in the area, galvanizing was essential in protecting steel and iron products from rust and corrosion, extending their lifespan, and enhancing their durability.

FORS Gold

Joseph Ash Chesterfield is the first galvanizing company in the UK to achieve FORS Gold accreditation for their transport fleet. The accreditation is no easy achievement, being the highest level the scheme achieves. Gold accreditation confirms our dedication to driver and vehicle safety, combined with improving operating practices through effective monitoring of fuel and tyre usage. If you’re looking for collection and delivery of your work to and from our site, you can be sure it’s arranged by a company that takes safety seriously.

Additional services

Outside of galvanizing, Joseph Ash Chesterfield also offers:

- Collection and delivery service: The site provides collections and deliveries throughout the Midlands and the North, and a daily milk run service within a 50-mile radius of the plant and the M1 corridor. The site’s dipping capabilities also mean we undertake work further away too, operating a fleet of seven articulated vehicles capable of carrying 28 tonnes each, plus five rigids which can also carry up to 15 tonnes. The fleet also has 48 trailers to maintain customers’ work.

- Full technical support: Providing customers with comprehensive technical support, offering guidance and assistance at every stage.

- On-site storage: With over 10 acres of available space, Joseph Ash Chesterfield offers ample on-site storage capacity, allowing customers to store materials conveniently before and after galvanizing.

- Trailer storage: Customers can take advantage of a designated area capable of accommodating up to 100 trailers, providing a secure space for transportation needs.

- Crane gantry area: The crane gantry area at Chesterfield features ramps and bays, enabling customers to load their containers and trailers efficiently and effortlessly under six external cranes.

- Fabrication pre-testing: Chesterfield includes a dedicated area where customers can assemble and pre-test their fabrications before taking them off-site for delivery to the end user.

- Truck driver facilities: Overnight and changing facilities are available for the comfort of truck drivers. Chesterfield also has a truck stop located directly opposite the plant.

- Forklift fleet: Chesterfield will soon be in the possession of the most up to date electric fleet of forklifts using an Opti Fleet computerised system. We have four 3.5 tonne and one 4.5 combi forklift trucks.

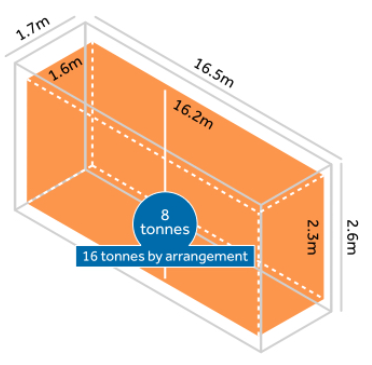

Bath size

The bath dipping size at Joseph Ash Chesterfield is 16.2m x 1.6m x 2.3m, and the team can dip 8 tonnes (or 16 tonnes by arrangement). Double dipping can also be undertaken (height and length).

The dimensions make it suitable for even the largest of steel fabrications.

Extended opening times

To help provide speedy turnarounds, the plant has extended opening hours for drop-offs and collections. Chesterfield also offers quick turnaround times (overnight and within 24 hours) by prior arrangement.

The highest standards

We’re proud to hold numerous accreditations and certifications for our work and the standards we galvanize to.

All our hot dip galvanizing is to BS EN ISO 1461 specifications. These standards help ensure a consistent, reliable coating is achieved from the process, with guidance on minimum specifications for coating thickness. We also hold the NQA ISO 9001:2015 accreditation for Quality Management Systems, ISO 14001:2015 for Environmental Management Systems, and ISO 45001 for Occupational Health and Safety Management Systems.