The UK’s widest bath at Joseph Ash Telford

Looking for the widest galvanizing bath in the UK? Look no further than Joseph Ash Telford!

When it comes to looking for the perfect galvanizing service provider, bath size matters. The right size galvanizing bath will ensure your steel fabrications are evenly and sufficiently coated in zinc.

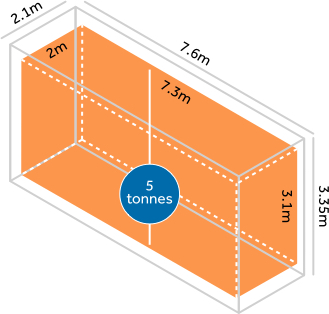

At two meters wide, the UK’s widest galvanizing bath can handle bigger and more complex projects than our competitors. Joseph Ash Telford is the ideal place to galvanize your fencing, structural steel, trailers, sculptures, or any other wide metal fabrications.

Why a wider galvanizing bath is better

There are numerous reasons why the width of our Telford bath makes it the ideal place to hot dip galvanize your metal fabrications.

Increased Capacity: A wider galvanizing bath can handle larger and more complex items. This allows you to protect bigger projects without needing to downsize them, saving you time and money. We can also process more of your items at once, reducing the overall turnaround time for projects. This allows us to meet tighter deadlines so you get your projects back quicker.

Reduced Handling: With a wider bath, you can process larger items without needing to handle them as much. Less handling reduces the risk of damage to the items and increases the efficiency of the handling process.

Better Coating Quality: A wider bath allows the molten zinc to flow more freely over all surfaces, both internal and external, of the metal. This ensures consistency with the coating’s thickness and quality. This is particularly important for complex items, where getting complete coverage on all surfaces can be difficult.

Cost Savings: By being able to process larger items in a single bath, we can save you money on energy, labour, and maintenance, helping you reduce your expenses overall.

The bath’s dipping dimensions are also 7.3 meters long and 3.1 meters deep, with a volume capacity of 5 tonnes. These dimensions make it capable of containing almost any large metal fabrication.

Contact our Telford site today to get a quote on your wide steel fabrications.

Liam Houghton, Assistant Divisional Manager at Premier Galvanizing Corby will be completing a 72-hole golf marathon in aid of the charity TOFS – a charity that supported his son through his difficult start to life.

The charity supports those who are born with OA/TOF, which stands for Oesophageal Atresia and Tracheo-Oesophageal Fistula. OA/TOF are rare congenital conditions of the oesophagus (food pipe) and/or trachea (airway) that affect 1 in every 3,500 people.

The charity is close to Liam’s heart, as his son Noah was born with OA/TOF. That’s why he wants to give back to the charity and partake in the golf marathon.

Liam commented on the charity:

“TOFS not only supported my son through the difficult start to his life, but also supported me and my fiancée through the struggling times by giving us incredible information and guidance to prepare us for the road ahead. This is my way of giving back to TOFS, so that they may continue to help future children and families in need.”

The fundraising event will take place at Market Harborough Golf Course on Thursday 29th June 2023, so there’s still plenty of time to donate.

You can show your support for Liam and the charity by donating to the cause here. Every donation will help the charity continue to help those with OA/TOF.

About the charity

TOFS was set up in 1982 by parents of children born with OA/TOF (some of whom are still associated with the charity). They became a registered charity in 1987.

Forty years on, they are still helping families through the challenges of bringing up a child with OA/TOF, VACTERL and associated conditions. Now, there is an increased focus on support for the cohort of adults who live with the consequences of being born with OA/TOF.

They are now the world’s largest English-speaking support group for those born unable to swallow. They have members in over 60 countries, and whilst they receive no government funding, they are a small charity with big aims. The charity is dedicated towards a world where those born with these conditions live long and healthy lives.

Widnes Galvanising, a leading provider of galvanizing services within the Joseph Ash Group, can now bring shot blasting and powder coating services to their customers. These new offerings bring Widnes Galvanising, which was acquired by the Joseph Ash Group in 2022, up to speed with other plants within the Group. Customers in the North West now have access to a wider range of finishing options, and can expect to save time and money on transportation and service fees.

Shot blasting is a highly effective process for removing rust, paint, and other contaminants from metal surfaces. It is essential for maximising the effectiveness of galvanizing and powder coating. Widnes’ other new offering, powder coating is a popular coating technique that provides a durable finish. It allows metal to be coated in a range of colours and textures while retaining the strength of galvanizing. Widnes Galvanising’s new offerings are perfect for making their customers’ steel fabrications stand out from the crowd.

Widnes Galvanising is committed to delivering the highest quality steel treatment services. With their new shot blasting and powder coating capabilities, the company is well-positioned to maintain its reputation as a leading service provider within the Joseph Ash Group. If you’re near the North West area, Widnes Galvanising is ready to strengthen your steel.

For more information about Widnes Galvanising and its services, please visit the company’s website at www.widnesgalvanising.co.uk or contact Gavin Jones at gavinj@widnesgalvanising.co.uk.

Another new face to the Joseph Ash Group, keen to introduce themselves! Paul Williams has joined our team at Widnes Galvanising as Maintenance Manager for the branch. We took the chance to speak with Paul in our latest ‘Meet the Team’ and find out all about him and his new role.

Meet Paul Williams:

Role: Maintenance Manager

Branch: Widnes

Started: 2023

Favourites:

Food: Love a Chinese banquet

Film: A good action film like the John Wick series is always a winner (I was lucky enough to use the Kiltech shot gun from the film while in the States). I’m also a big F1 fan and love watching the race on weekends.

Pastime: I try and keep fit, attending my local Men’s Hub facility in Warrington 3-4 times a week, running and cycling now and then. I also enjoy meals out with my wife and kids, and long beach walks with our border collie Rosy.

Can you give a brief overview of your role?

My role as Maintenance Manager is to keep production running smoothly. I liaise with contractors, management, and staff to keep the daily operations of the plant working as they should. Basically, if it breaks, it’s my job to fix it.

Can you give us some history on your career?

My previous job was as an electrical contractor working on all manner of sites, from hospitals to petrochemical sites. This came to an end in 2009 when I took up a maintenance role for another galvanizing company, which was my introduction to the galvanizing industry.

What drew you to the company?

I saw the job advertised at Joseph Ash and saw there was potential to grow, improve and challenge myself in my first management role. I love a challenge and felt that my skillset very much matched the job advertised, and I wanted to progress.

What is your favourite/most memorable project to date?

Being so new to the company I’m just starting to get my teeth into our first round of improvement works over Easter. I actually enjoy the planning stages and seeing the various works come together to reach the common goal.

What projects are you looking forward to in the coming year?

I’m generally looking forward to improving the site, how we operate, working as part of a larger team and increasing production.

Tell us something that people might find surprising about you.

People normally double take when I tell them I’m a professional wrestler (WWE style) and have worked on shows up and down the country. I have also been lucky enough to wrestle internationally in Belgium, Australia and the United States. I even had a small part in the Hollywood movie “Fighting With My Family”, starring The Rock.

I’ve also completed a few marathons – one ultra marathon and a century bike ride (not on the same day though!). I also help coach a local football under 16 team (Cromwell Thunderbolts) which my son plays for too, so I’m quite busy generally.

2023 is the year of incredible long service milestones, as Dalit Singh recently celebrated 45 years at the Company! It was only last month on Valentine’s Day that Mick Jackson celebrated 40 years at Joseph Ash Galvanizing. Now, Dalit from Joseph Ash Walsall has his long service recognised.

Dalit started working for Joseph Ash in March 1978. He has worked through every role in the Walsall galvanizing plant, including Shift Supervisor for over 12 years.

Dalit first started his job with a company called Walker Brothers Galvanizing. The company was later taken over by Hill & Smith, Joseph Ash Galvanizing’s parent company. His first job was in Jigging Materials, and he then moved to become a Pot Man before his aforementioned Shift Supervisor role.

Amy Leachman from Joseph Ash Walsall commented on Dalit’s 45 years:

“Through his time, he has been a fantastic employee, with vast experience in our industry and someone that the division has been able to rely on. I personally have learned from Dalit’s expertise during my time spent with the production team and can see just how important a role he has played!”

Thank you for all your years of service, Dalit!

The Easter Holidays are fast approaching, which means our plants’ opening times will be affected.

All plants will be closed over the Easter bank holiday. If you’re looking for metal treatment services soon, please note these closures and make sure to book your projects for galvanizing in advance.

Every plant will be closed on Friday, 7 April and Monday, 10 April 2023. The plants will reopen on Tuesday, 11 April 2023.

We hope you have a well-deserved break!

We speak to Jess Ramanouski, Internal Sales Executive at Joseph Ash Galvanizing’s Widnes site, to find out a bit about her and her role at the site.

Meet Jessica Ramanouski:

Role: Internal Sales Executive

Branch: Widnes

Started: February 2023

Can you give a brief overview of your role at the company?

My role as Internal Sales Executive at Joseph Ash Galvanizing’s Widnes site involves organisation and management of internal sales in our plant. This includes making sure our customers are well looked after, as well as assisting them with projects and providing quotations for them.

I have knowledge in all departments in the plant and my knowledge is ever-growing. I have been in customer service for over 10 years, and I always make sure customer satisfaction is a top priority.

What was your career like before joining the company?

When I finished school, I did an apprenticeship in Business Administration. I worked in a forklift training centre for seven months and loved every minute of it. Due to my age, I decided to complete my A-Levels to save complications with funding as I got older. After this, I spent four years at Liverpool Hope University studying for a BA in History & Media and Communication, and an MA in History. During this time, I worked for a supermarket as a Team Leader and qualified as a Theatrical Makeup artist.

I met amazing people and learnt many transferrable skills. I enjoyed my time there; however, I was always yearning for a graduate job where I could put my knowledge and skills to good use. This led me to my current role at Joseph Ash Widnes and I have loved every minute since!

What drew you to the company?

Widnes Galvanising Ltd is a local business to me. It’s where my dad worked when I was a child, and my little brother works in the yard. I heard a lot of positive things about the company and people after it had been taken over by Joseph Ash and began trading as Joseph Ash Widnes. I did some research and liked the sound of the ethics and eco-friendliness of the company, so I decided to apply.

What are you looking forward to in the coming year?

I am looking forward to the positive changes that have been implemented over the past year, along with our new organisation and systems in the plant. I am also looking forward to ever-growing customer relationships and gaining even more knowledge in my role.

Tell us an interesting fact about yourself.

I am a huge fan of makeup and the art of drag. I am a qualified makeup artist, and I will often have a face full of makeup on, including rhinestones. I am obsessed with RuPaul’s Drag Race and when I am not in work, I will spend time binging episodes.

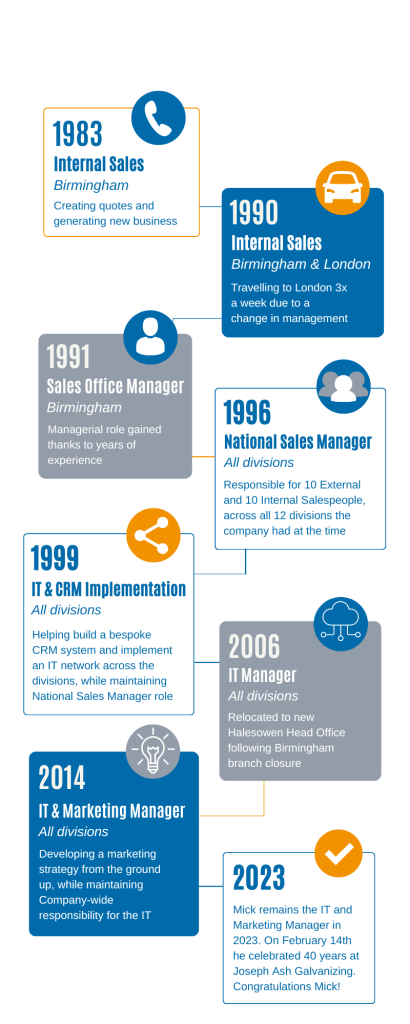

It’s Valentine’s Day, 2023. Forty years ago today, Mick Jackson started his career at Joseph Ash Galvanizing and is now celebrating his ruby anniversary with the Company!

Before starting at Joseph Ash, he sold tape for an engineering company, and had previously completed an apprenticeship as an Electrical Technician. Over the years he has taken on numerous positions, and he is well-respected by all those around him.

Staff at the Halesowen Head Office surprised Mick with gifts, including alcohol and chocolates. He and his colleagues will also be celebrating the occasion at a local restaurant.

We recently caught up with him to look back at his time at the Company and the memories he’s had along the way.

Mick’s journey through Joseph Ash…

“Before starting at Joseph Ash, I completed an apprenticeship as an Electrical Technician, and sold tape for an engineering company. I then joined Joseph Ash in 1983 as ‘Internal Sales’ at our old Birmingham head office .This involved creating quotes and generating new business. There were only two galvanizing divisions at the time – Birmingham and Telford.

“During the next few years, the company expanded through several acquisitions, growing quite rapidly. During these years I gained more experience in my sales role.

“In the early 90’s there was a requirement at our London division for someone experienced to manage their commercial sales activities. I was asked if I wanted to help on a temporary basis while maintaining my role at Birmingham. For the next 18 months, I split my time working in London for three days a week and Birmingham for the other two days. Once the London operation had stabilised, I returned to Birmingham full time and, given my excellent work in London, I was promoted to Sales Office Manager at the Birmingham Head Office.

“I spent some more years gaining sales experience (especially externally) visiting customers, and around ’96 I’d progressed to National Sales Manager, holding responsibility for sales across all twelve divisions we had at the time. There were about ten External Sales Engineers and twelve Internal Sales staff whom I was responsible for.

“Approaching the new millennium, the Company needed a new central sales system. It was at this time I’d agreed to a temporary project role to help build it. I didn’t have any prior IT knowledge, but I had commercial sales experience. As such, this was invaluable in helping create a new CRM system for the company. Working with a software house, we heavily be-spoked their ‘off the shelf’ CRM system and ended up with the CRM system still in use today. I was also involved in helping to facilitate other new advances in providing a wide area network between our divisions. This CRM helped us gain a 360-degree overview of our customers, greatly improving our sales and reporting, and bringing our divisions closer.

“That was only supposed to be a two-year role, but other bits were added to the system over time. I reskilled in IT, learning on the job. I never went back to Sales.

“In 2006, the Birmingham head office shut down and we relocated to our current Halesowen head office. Thanks to the experience I’d gained in my IT role, I became IT Manager for the Company.

“Around 2014, it was decided we desperately needed to improve our marketing efforts. There was very little marketing being done by the company and no great efforts had been made towards this area, historically. So, using my previous marketing experience from my National Sales Manager role, I agreed to “temporarily” split my time between IT and Marketing to help establish this area of the business.

“We developed a solid marketing strategy, including the creation of our social media channels and exhibiting for the first time, spreading awareness of Joseph Ash and its brand all over the UK. And that leads to where I am today, as Joseph Ash’s IT and Marketing Manager. I’m also current Chair of the Galvanizers Association Marketing Committee.

“A lot has happened over 40 years, as you’d expect. Some good, some not so good, mostly good though! There’s lots of great people at Joseph Ash. Some have become very good friends. They make it a great place to work.”

When asked what his biggest achievements over the past 40 years were, Mick responded:

“Creating the CRM system was a huge achievement. It’s helped the company out massively and allowed us to grow and manage our customer base. I’m also proud of creating our overall marketing strategy, going from almost nothing to what we have today.”

Mick’s favourite memory during his 40 years is a touching one. He explains:

“I’d received a letter from an ex-employee. She was initially one of my internal sales execs, then she worked for me as an IT trainer, helping train the workforce in the use of the CRM system. She’d written the letter to thank me for helping her develop as an individual, develop her career and grow her confidence. She said she would always think of me as the person who opened her future. It was really nice; I still have it at home.”

Thank you, Mick, for all your years of hard work and dedication to the Company!

Apprenticeships are a valuable achievement, whether you’re newly out of school, or if you have years of working experience already behind you. For National Apprenticeship Week 2023, we decided to interview one of our current apprentices, Matthew Phillips for our latest ‘Meet the team’ article. Matthew is a Customer Service Manager at our Chesterfield branch. He started his Level 3 Team Leader course in June 2022, and has been with Joseph Ash since 2007.

Tying into this year’s theme of Skills for Life, we decided to ask him all about his apprenticeship experience, and learn about how he’s been able to progress his career.

Meet Matthew Phillips:

Role: Customer Service Manager

Branch: Chesterfield

Apprenticeship: Team Leader (Level 3)

Started: 2007 (at Joseph Ash) / June 2022 (apprenticeship)

Can you give us a brief overview of your current role at the company?

“I started at Joseph Ash in 2007 as a Customer Service Manager and my Team Leader apprenticeship in 2022. I’m due to finish my course in about six month’s time.

“As Customer Service Manager, I’m responsible for managing key accounts and day-to-day contact with customers. I have over 15 years’ experience in the industry, building key relationships with customers and clients. I help produce formal quotations, assist with production and transport requirements, and manage existing projects and provide site tours and visits.”

Why did you choose to do an apprenticeship, and how has it impacted your career?

“I wanted to do an apprenticeship to further my training and knowledge. The training has been very useful in my development as a manager. The course has covered a wide range of topics, providing me with skills I can use within my role. This has helped me achieve my sales targets and develop my operational and project skills.

“The best thing I’ve learnt during my apprenticeship is gaining an understanding of the impact of unconscious bias and emotional intelligence.

“I’m looking forward to developing my team and managing more projects in the coming year. I’m more equipped to do these thanks to the skills I’ve learnt in my apprenticeship.”

Do you have any advice for someone who is interested in completing an apprenticeship?

“Enjoy the training, and use the information provided within your role.”

When asked about his interests outside of his apprenticeship and career, Matthew commented:

“I’m a very sporty person and enjoy playing football and running. I play for two football teams on a Saturday and Sunday, and support Derby County (best team in the East Midlands). I also enjoy spending my spare time with family and friends, and going out for nice food and drinks. When using my holidays, I like travelling the world seeing different cultures and going on new adventures.”

“Believe it or not I’ve once appeared on a TV soap called Peak Practice when I was younger.”

Contact Joseph Ash Galvanizing today if you’re looking for you next career step or any apprenticeship opportunities!

In October 2022, Joseph Ash Ltd acquired Widnes Galvanising, which became the ninth plant for the Group. We thought this would be a good opportunity to interview Widnes’ Commercial Manager, Gavin Jones in our latest ‘Meet the team’ article to find out a bit about him and what his plans are for the division.

Meet Gavin Jones:

Role: Commercial Manager

Branch: Widnes

Started: 2015

Favourites:

Food: Anything Asian (Thai, Indian, Chinese, Japanese, Malaysian, Vietnamese etc.)

Film: Step Brothers. I have a very immature sense of humour and this is right down my street!

Pastimes: Football. I’ve always played football and used to play for Saturday and Sunday football teams, but when you get older and have kids you don’t have the time anymore. However, I still play indoor football every Wednesday evening with my mates, which remains a highlight of my week.

Can you give us some history on your career?

“I’ve been a Commercial Manager since June 2020 but have been with Joseph Ash since May 2015. I previously held the position of Safety, Health, Environmental and Quality Manager at the Telford branch.

“Before Joseph Ash, I worked as a salesperson for a medical equipment supplier. I travelled all over the UK but decided to find a position closer to home when my wife was pregnant with our first child.

“I lived in Telford at the time a ‘Management Trainee’ position became available at the Telford branch. After meeting with Stuart Whitehouse, Stuart Cobourne and Tracie Lockley at the interview stage, I could tell it was the kind of company I wanted to work for.”

Can you give us an overview of your day-to-day?

“In my current role as Commercial Manager at Widnes Galvanising it is my responsibility to ensure the division secures sufficient sales revenue to achieve our targets.

“My day-to-day tasks include customer analysis, prospecting, and quoting all enquiries.

“Aside from the sales side of the role, I often refer to myself as a kind of project manager as I am the link between our customers, production and transport. I also spend many days on the road visiting customers for all kinds of reasons, such as advice on their designs and discussing pricing.

“This year I am getting far more involved with the overall running of the business.”

What are your goals for the Widnes plant?

“My goal is to grow the business and increase our weekly tonnages by 20% while maintaining the excellent turnaround times and service. The quality of Joseph Ash’s galvanizing has always been first class, so I’m hopeful that new customers will see the benefit of using Widnes Galvanising going forward.”

Tell us an interesting fact about yourself.

“I’m a massive foodie and I’m always trying new recipes when cooking at home. I worked as a chef in a pub kitchen, and an Indian restaurant whilst I was at university. I haven’t ruled out the possibility of opening my own restaurant one day.”

If you’d like to get in touch with Gavin at Widnes Galvanising to discuss your hot dip galvanizing requirements, you can reach him at gavinj@josephash.co.uk.