July 2020 newsletter

Welcome to the Joseph Ash newsletter. Hot off the press today!

To read the July 2020 newsletter from Joseph Ash Galvanizing click here.

To receive a copy of the newsletter in your inbox each month, please subscribe. Simply scroll to the bottom of the page and look for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too! Please feel free to get in touch with your news, and we’ll try to feature it.

Padel Tennis was first invented in 1915 by a Minister in New York who wanted to provide recreational activities for children in local neighbourhoods. Fast forward more than a century and it has become widespread in the US, it’s growing rapidly in Europe, and it’s starting to make its mark on the UK. JB Corrie, Joseph Ash Galvanizing, the Lawn Tennis Association (LTA) and Chichester Racquets and Fitness Club are helping with the movement to make the sport more popular.

Padel Tennis is a game that resembles lawn tennis and squash. It is played on a smaller court to lawn tennis, with lower nets, and walls that the balls can be bounced off, in a similar way to squash. The racquets are solid without strings, and the tennis balls are depressurised.

It is a great sport for families and people wanting to newly engage in tennis as the ball can be kept in play for longer.

At present, there are only 72 Padel Courts in Britain, but the LTA is on a mission to help this number grow. They are doing this by providing sports club with £50,000 grants to build new Padel Courts, which is payable over a 10-year term.

Padel Court manufacturing

Chichester Racquets and Fitness Club in West Sussex have taken up the challenge and they will be installing their first Padel Courts in the next few months. JB Corrie, a fencing manufacturer based in Hampshire, is helping by manufacturing the courts. And our Medway plant is helping by hot dip galvanizing and powder coating the steel.

JB Corrie has been in business for over 100 years providing specialist fencing installations and supplies. They have a wealth of experience in designing and fabricating fencing for all types of venue, including sports facilities. They also have a strong interest in the Padel Tennis movement, and a long relationship with the LTA, which makes them the perfect fit for this job.

JB Corrie provides high levels of quality and meet all the necessary fencing industry standards such as ISO 9001:2008 and UVDB Verification. This strong adherence to industry standards is an important consideration for this project as the LTA insist on a particular thickness of steel for the fencing and for LTA specified projects. Corrie Padel is hot dip galvanized to BSEN ISO 1461:2009 and power coated in a range of over 300 standard RAL colours to BSEN 13438.

JB Corrie also supply 12mm toughened glass to BSEN 12150 with an option for heat soaking, as well as printing options for club logos.

JB Corrie are currently manufacturing the fences and will be delivering them to Joseph Ash Galvanizing in the week beginning 3 August. (Watch this video to see a plan of the fences.) The team at Joseph Ash Medway will then spend a few weeks hot dip galvanizing and powder coating the steel ready for it to be delivered to Chichester Racquets and Fitness Club and installed on their grounds.

Hot dip galvanizing is important because it provides a long-life, low-maintenance corrosion protection which safeguards steel from atmospheric attack, especially in coastal counties such West Sussex.

The final powder coating finish further protects the steel with a low maintenance, long lasting, colourful covering and adds an attractive final finish.

The ball is in!

Once full COVID restrictions are lifted, Chichester Racquets and Fitness Club will be hosting an open day to launch the new courts. They will also be inviting some international Padel Court champions to the Club to showcase the sport.

We hope this effort, combined with the efforts of the LTA, JB Corrie and Joseph Ash, will help to grow the amount of people interested in the sport.

Keep tabs on the project

Keep checking our website over the next few months to monitor progress on this project.

Please keep up with our social media too (links below) to see photos and videos of the fencing for the courts as they are manufactured, galvanized and installed.

If your tennis or fitness club is thinking of installing Padel Courts, please also get in touch with JB Corrie, as they’d love to help with the process.

Social media:

Joseph Ash Facebook

Joseph Ash Instagram

Joseph Ash Twitter

Joseph Ash Linkedin

JB Corrie Facebook

JB Corrie Twitter

JB Corrie YouTube

Chichester Racquets and Fitness Club Facebook

Chichester Racquets and Fitness Club Instagram

Chichester Racquets and Fitness Club Twitter

LTA Padel instgram

LTA Padel Twitter

In 2019 a project was underway to add a new canopy roof to the Ken Rosewall Arena in Australia. Macalloy was engaged to provide the steel tension rods. And Premier Galvanizing Hull (part of the Joseph Ash Group) was engaged by Macalloy for hot dip galvanizing.

The Ken Rosewall Arena was originally built at the Sydney Olympic Park Tennis Centre for the 2000 Olympic Games. With seating for 10,500 people it has proved a popular venue for tennis fans ever since.

In 2019 it was redeveloped to become a multi-purpose indoor arena, and it is now also the home of netball in New South Wales.

As part of the redevelopment it changed from being an open arena to a semi-enclosed all-weather venue. A significant structural engineering undertaking!

The project – designed by Cox Architecture, in conjunction with Arup – required steel tension rods for the canopy, with steel cables forming the shape of the roof and providing support. Due to the scale of the project and the size of tension rods required, Macalloy was chosen to provide the rods.

Even though Macalloy are based in the UK, and the project was on the other side of the world, they were the perfect company as they’re the only fabricator in the world who can provide such large tension rods.

Because the rods are made from steel, and steel corrodes and rusts if left untreated, Macalloy engaged Premier Galvanizing Hull to hot dip galvanize the metal.

Premier Galvanizing was not the first galvanizer to start the job though. Macalloy had previously engaged another galvanizer who provided inadequate design advice for hot dip galvanizing, and the job started to fall behind schedule.

For galvanizing to work, it’s important for galvanizers to talk to individual fabricators and impart advice on how to prepare steel for galvanizing. For example, to achieve the best quality zinc coating, it is crucial to ensure that molten zinc can flow freely over all surfaces, external and internal. So, where there are sealed hollow sections or cavities, vent and drain holes are essential.

Macalloy called Premier Galvanizing to see if they could help with their job and get the project back on track, and Andrew Tweddle (Commercial Manager at Premier Galvanizing Hull) drove to Dinnington in South Yorkshire to look at the steel rods and suggest some improvements.

Macalloy were happy for Premier Galvanizing to hot dip galvanize a trial batch. Pleased with the results, they engaged them to complete the whole job.

In total Premier Galvanizing hot dip galvanized 204 tension rods, with the largest weighing in at about 600 kilos each, with some reaching almost 10 metres in length. It was a huge job… almost 50 tonnes of steel.

Premier Galvanizing were also pleased to help Macalloy with some of the project logistics by collecting the steel with their fleet of trucks and delivering it back to Dinnington once they’d completed their part of the job.

Andrew Tweddle said: “Working with Macalloy has been a pleasure, and hopefully the start of a good working relationship. We spent a good few weeks hot dip galvanizing the steel and we were proud of our efforts and our ability to provide sound technical advice. We were also proud to help Macalloy get the project back on track – in fact our hard work helped them to get eight weeks ahead of schedule.”

The new roof for the Ken Rosewall Arena was finished by Cox Architecture and Arup in December 2019, just in time for the ATP Cup in January 2020. We hope it continues to be a great home for tennis and netball in the coming years.

You can read more about the project here.

Welcome to our latest newsletter! Hot off the press today!

To read a copy of the June 2020 newsletter from Joseph Ash Galvanizing click here.

To receive a copy of the newsletter in your inbox each month, please subscribe. Simply scroll to the bottom of the page and look for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too! Please feel free to get in touch with your news, and we’ll try to feature it.

Designed and fabricated by Luke Perry. Hot dip galvanized by Joseph Ash Telford.

Earlier this year, a gigantic sculpture was added to the Lemur Wood of Dudley Zoo and Castle (DZC), in the Midlands. The stunning sculpture depicts a ring-tailed lemur, with a baby on its back, leaping from one pole to another.

Designed and fabricated by Luke Perry, an English artist renowned for creating huge works of art, the sculpture also includes words on the poles about the threats to the species. Threats which include hunting, logging, deforestation, and the pet trade.

DZC commissioned the sculpture as they wanted to educate visitors not only about the threats to lemurs (90% of the population currently faces extinction), but also about ongoing threats to other species.

According to the Express & Star website, Derek Groves, the Zoo Director, said: “[The statue is] built around the concept of lemurs being an endangered species, and whether they survive in the wild is whether humans take action and help to stop them being wiped out.

“The lemur is on one post and the question is whether it gets to the other side. It’s down to us.

“[The statue is] not just about lemurs. It’s about all animals and their habitats, so hopefully it will [not only] be a photo opportunity, but also [a chance for] people to look at the statue and get the message.

“Hopefully it will get people to think more about the animals and their habitats and change their behaviours.”

Titled ‘A Leap of Faith’, the sculpture – made from sheet steel – took six months to build and at 30ft is one the largest sculptures Luke has ever fabricated.

Because steel is prone to rust and corrosion if left untreated, Luke engaged Joseph Ash Galvanizing to hot dip galvanize it.

Hot dip galvanizing is important because it provides a long-life, low-maintenance corrosion protection which safeguards steel from atmospheric attack.

Mick Jackson from Joseph Ash Galvanizing said: “It was a pleasure to be asked to treat the steel for this sculpture. Having worked on an installation for Luke a few years back (Queen Aethelflaed, Lady of the Mercians) we know how amazing his work is, and we know how important it is to protect the steel from the environment for many years to come.

I was at DZC on the day of the sculpture unveiling, and it was wonderful to see it in its final place.”

As supporters of the Lemur Conservation Association, Dudley Zoo has always had a strong interest in lemurs. The zoo is also home to five different species of lemur – ring-tailed, black-and-white ruffed, red ruffed, collared and black. Luke had to study the creatures for many hours so that he could accurately depict a lemur in his statue.

According to the Dudley Zoo and Castle website, Luke said: “Thank you to DZC for giving me the opportunity to do something a bit different. It’s been a challenge and it’s been the first time I’ve had to put wheels on a sculpture and nearly take a wall out just to get it out of the factory!

But I’m so very pleased with it and I’m pleased people like it.”

Dudley Zoo and its visitors are thrilled with the sculpture, as is Luke Perry. We were also thrilled to be a part of a such a huge and beautiful project, and something which will impart an important conservation message.

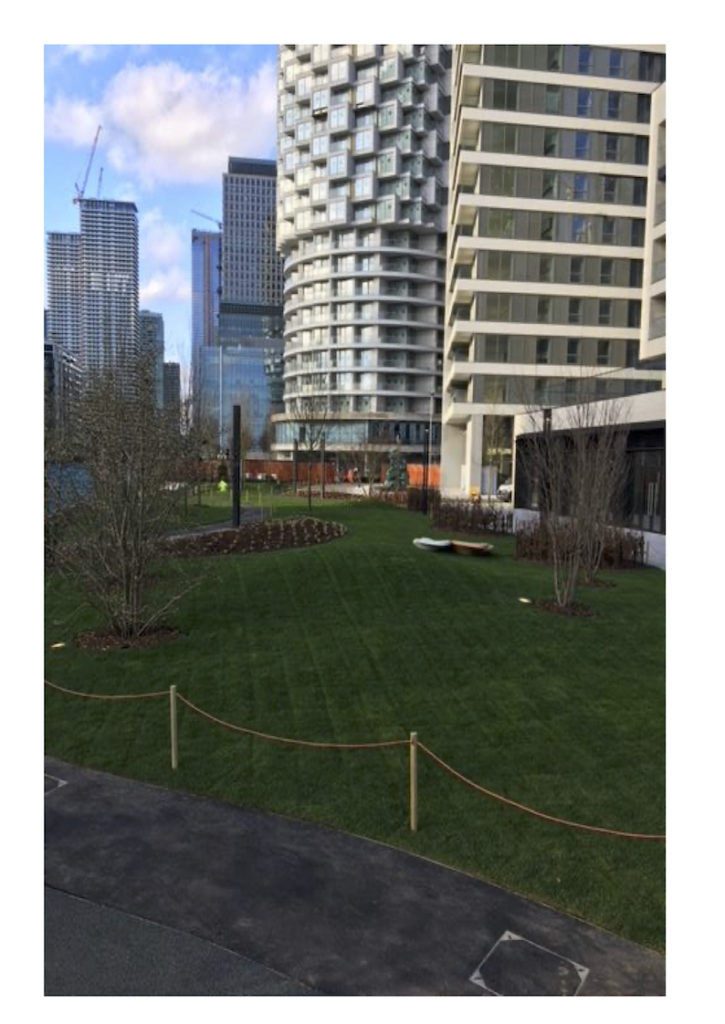

Wood Wharf is a new neighbourhood in Canary Wharf, London. When the exciting development work completes in 2023 it will include offices, residential homes, community space, leisure and entertainment sites, and retail space.

As the neighbourhood will contain 3,300 homes, a new children’s play area has recently been designed and built by Willerby Landscapes, based in Edenbridge, Kent.

As part of the project, Willerby Landscapes engaged Crest Engineering Ltd to fabricate some of the play equipment, and Crest engaged Joseph Ash Medway to protect the steel.

You can see some of the photos here:

There were many elements to the play area, including bridges, a climbing frame, seating and a seesaw.

Joseph Ash Galvanizing collected the steel from Crest Engineering. It was taken to the Joseph Ash Medway plant so that our team could protect it for many years to come with a hot dip galvanized and powder coated finish. The powder coating elements alone amounted to about 200kg of mild steel and the client chose pink and pearl violet RAL 4011 as the colours. The steel was then delivered back to Crest Engineering’s site in Marden, Kent, by our delivery team.

Tim Palmer at Joseph Ash Medway said: “We were very proud to treat the steel for this wonderful project and it will be great to see the playground in use when the first residents of Wood Wharf begin to move in this Summer (COVID allowing of course). It was also great to work on a project for Crest Engineering Ltd, and we look forward to working with them again should another project arise.”

Millions of people every day face the reality of living with a mental health illness – an illness that others may not see, know about or understand. Whether it’s anxiety, stress, depression or low moods, to illnesses such as schizophrenia, bipolar or Alzheimer’s, these conditions can have a dramatic effect on a person’s life.

At Joseph Ash Galvanizing we believe we have a duty of care and a moral obligation to our employees to help them have good mental health, especially as the workplace – regardless of industry or type – can sometimes be a place of additional stress or anxiety.

The Mental Health Foundation says: “We believe in workplaces where everyone can thrive. We also believe in the role of employers, employees and businesses in creating thriving communities.”

We believe in this too, and it’s why we have recently engaged in B.U.D.I.E.S training for good mental health.

The Mental Wellbeing B.U.D.I.E.S. virtual classroom is a one-hour programme to initiate mental health support in the workplace. The virtual classroom course is helping to give our staff the listening skills and B.U.D.I.E.S. framework to support their colleagues throughout the year.

The B.U.D.I.E.S framework focuses on:

B – Build a helping relationship

U – Understand

D – Determine if your colleague is in crisis

I – Inform about self-help

E – Encourage professional help

S – Safety at all times

The course stresses the importance of listening skills and how to deal with a crisis. It also encourages people to have ‘Wellbeing B.U.D.I.E.S.’ at work – someone to talk to if you’re in need of a friendly ear.

Before COVID, we were due to complete some Mental Health First Aid (MHFA) training courses, but as these were going to be face-to-face, we’re pleased to have found an alternative in the B.U.D.I.E.S. virtual classroom.

A number of our team have already taken the B.U.D.I.E.S. training, and we have two more sessions scheduled for this week.

Later this year, we will complete the MHFA training and we’ll also provide colleagues with full contact details for support including:

- Their local BUDIE (telephone, email, Whatsapp)

- Contact details for our Employee Assistance Programme

- Local support networks

The Mental Health Foundation says: “Mental health is something we all have. When we enjoy good mental health, we have a sense of purpose and direction, the energy to do the things we want to do, and the ability to deal with the challenges that happen in our lives.”

At Joseph Ash Galvanizing we aim to promote good mental health, and foster purpose, direction and the ability to successfully navigate through life.

Welcome to the Joseph Ash newsletter. Hot off the press today!

To read a copy of the May 2020 newsletter from Joseph Ash Galvanizing click here.

To receive a copy of the newsletter in your inbox each month, please subscribe. Simply scroll to the bottom of the page and look for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too! Please feel free to get in touch with your news, and we’ll try to feature it.

Health and safety has always been important to Joseph Ash Galvanizing and Premier Galvanizing, and this is especially the case during these COVID times. Since the Coronavirus pandemic began to affect the UK, Joseph Ash Galvanizing and Premier Galvanizing plants have remained opened, but we have been working safely, staying Covid-19 secure.

To help customers and suppliers feel secure whilst working with us (either when meeting with our delivery drivers, or when visiting our plants), we have put extra measures in place in place in each plant to comply with the Government’s guidance on managing the risk of COVID-19. For example:

- We have cleaning, handwashing and hygiene procedures in line with guidance.

- We have taken all reasonable steps to help people work from home.

- We have taken all reasonable steps to maintain a 2m distance in the workplace.

- Where people cannot be 2m apart, we have done everything practical to manage the risk of transmission.

Each Joseph Ash Galvanizing and Premier Galvanizing plant has recently been assessed against the guidelines, and has been issued with a certificate to show compliance.

For further information about how we’re managing risk during this epidemic, please also read our Epidemic Health and Safety Policy.

Welcome to the April 2020 Joseph Ash Galvanizing newsletter. Hot off the press today!

To read a copy click here.

To receive a copy of the newsletter in your inbox each month, please subscribe. Simply scroll to the bottom of the page and look for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too! Please feel free to get in touch with your news, and we’ll try to feature it.