Meet the team at Corby

We’re pleased to introduce some team members at our Corby (Premier Galvanizing*) plant. From left to right we have David Prattis, Lisa Sutton, Daren Stevens, Anna Stocks, Bob Preston, Heather Elmore and John Frankland.

Find out more about the team below:

David Prattis joined Premier Galvanizing Corby as General Manager in September 2019. He has over 30 years’ experience in Steel and Aluminium Coil Coating, supplying product into the Construction and Leisure Industries. Before joining Premier Galvanizing, he spent 10 years as Plant Manager for an International Coil Coating Company based in the UK and The Netherlands.

Lisa Sutton is the Corby Office Manager. She is a long-standing member of the team, having worked for the company for 14 years, ensuring the smooth operation of all business administration.

Daren Stevens has been with Premier Galvanizing since it originally opened in September 2002 as an experienced Operative. He previously worked with Bob Preston (below) at Clark Steel. Working his way up from Shift Supervisor, he became Works Supervisor, then Galvanizing Manager. He was promoted to Operations Manager last year. Having worked at the plant for many years, Daren has expert knowledge in running a busy galvanizing plant.

Our Corby plant operates eight dedicated lorries to service customers’ needs giving a fast turnaround of typically 2-3 days. As Operations Manager, Daren also ensures these collections and deliveries run smoothly.

Anna Stocks is the Financial Controller for Premier Galvanizing and operates across two plants (Corby and Hull). She is a valuable member of the team and has worked for the company since 2016.

Bob Preston has a wealth of experience in galvanizing, having worked in the industry since 1972. Throughout his career, Bob has progressed through the galvanizing business from Shift Operative, to Works Manager, to Production Manager and onto his current position as Production Director. In this role Bob supports all other members of the customer focused team in delivering an exceptional all-round service.

Heather Elmore is experienced in administration, bookkeeping and credit control. She has worked with the Corby team for over three years providing much needed assistance in the office.

John Frankland joined Premier Galvanizing in September last year as Sales Manager. John is new to the galvanizing industry and has a background in Capital Equipment Sales to the manufacturing and metal fabrication sectors. John works at our Corby plant providing hot dip galvanizing services from Mansfield and Nottingham in the north, following the A1, M1 and M11 routes down through the country and covering the north half of London from Essex in the East through to Berkshire in the West.

The entire Corby team take pride in delivering an unbeatable service in terms of quality, turnaround and doing exactly what they promise. If you have any questions or queries, or if you’d like to place an order, please get in touch with the Corby team.

*Premier Galvanizing is part of the Joseph Ash Group.

Art Metal is a family run Blacksmiths based in Bromsgrove, Worcestershire. Combining fabrication and craft skills, they provide bespoke designer metalwork for a range of customers – residential, commercial and industrial.

Their work includes gates, fences, railings, arches, staircases and bridges, as well as water features, sculptures and public works of art.

A recent commission from one of their clients was a request to fabricate a large centre piece garden feature in the shape of a thistle.

The 10 ft high and 5 ft wide flower weighed over 250kgs, took four weeks to make and looked elegant and majestic once sculpted.

The sculpture was crafted from mild steel, and to protect it from the elements for many years to come, Art Metal turned to Joseph Ash Walsall to get the artwork galvanised. Galvanizing is important for steel because it provides a long-life, low-maintenance corrosion protection which safeguards steel from atmospheric attack.

Paul Hudson, Sales Manager from Joseph Ash Walsall said: “It was a pleasure to galvanise the steel thistle. Thistles can often be overlooked in their beauty compared to other flowers, but Art Metal have done justice to their spikes and elegance.”

Adam Barrett from Art Metal said: “We enjoyed fabricating this garden centrepiece for our client and wanted to ensure its beauty would be enjoyed for many years to come by sending it to Joseph Ash Walsall for a galvanised finish. Our client loves the finished sculpture and has now asked for some matching thistle styled gates, which we’ll fabricate later this year.”

Welcome to the latest Joseph Ash Galvanizing newsletter. Hot off the press today!

To read a copy click here.

To receive a copy of the newsletter in your inbox each month, please subscribe. Simply scroll to the bottom of the page and look for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too! Please feel free to get in touch with your news, and we’ll try to feature it.

Lawley and Overdale Parish Council, based in Telford, are very active each year in commemorating local residents who have contributed as military and civilian servicemen and women in the two World Wars and later conflicts. A great example of this includes placing 200 poppies on lampposts across the Parish every year.

A recent – and perhaps grander – project to remember the sacrifices, includes a permanent structure for the area: stunning hot dipped galvanized steel poppies, a memorial and a roll of honour. The installation was a vision of the Parish Council for about 3-4 years, and recently Art.Fabrications – with some help from Joseph Ash Walsall – made it possible.

Art.Fabrications is a specialist fabricator and installer of metal sculpture and artwork. Based in Nuneaton, Warwickshire, it was the perfect company for the project as its team members are able to spend time understanding the original concept and idea and produce a piece of art or sculpture that authentically captures the original vision.

After being let down by a number of other companies, members of Lawley and Overdale Parish Council met with Art.Fabrications, commissioned the project and the team got to work.

Art.Fabrications made the main structure for the poppies from sheet mild steel, which was zinc sprayed and painted. The actual poppies themselves – weighing 90kgs – which run-up one side and onto the top of the structure were fabricated and then sent to Joseph Ash Walsall for galvanizing.

Mick Jackson from Joseph Ash Galvanizing said: “We have worked with Art.Fabrications on a number of projects over the years, galvanising their steelwork to ensure a good quality finish and protection from the elements which would otherwise lead to corrosion and rust if left untreated. We were thrilled to galvanise the stunning poppies for Lawley and Overdale Parish Council, at our Walsall plant. Our treatment should ensure the local residents can enjoy the poppies for many years to come.”

Andy Langley from Art.Fabrications said: “We love listening to someone’s vision about an art installation, understanding their reasons behind the project, and then taking it on and getting to work. We were very happy to fabricate such an important piece of work for Lawley and Overdale Parish Council, partly because they’d had the vision for a good few years, but also because it’s so important to commemorate our servicemen and women. We hope it is a structure that will provide comfort to people in the local community who have lost someone in the two Great Wars or more recent conflicts.”

The hot dipped galvanized poppies will be a key focus for this year’s Remembrance events in September.

Matt Green and Myles Durward from Joseph Ash nominated for In-Comm Training and Business Services Awards

On 7 June 2019 the annual In-Comm Training and Business Services Awards were held at the ICC in Birmingham. The Awards celebrate and reward young apprentices and adult learners across the West Midlands, and this year team members from Joseph Ash Chesterfield were there to celebrate their training achievements.

Matt Green and Myles Durward have both been completing JAC Level 2 of In-Comm’s BIT training. As part of this course they are learning new skills to take back to Joseph Ash Chesterfield. Skills include looking at ways to be more efficient (and remove wastage) in the following plant processes: Overproduction, Transportation, Waiting, Inventory, Defects, Motion and Process.

Myles and Matt were both nominated for the ‘Learner of the Year: Continuous Improvement’ award, and on the night, Matt walked away with a ‘Highly Commended’ accolade.

Six other team members from Joseph Ash Galvanizing have also completed their Level 2 training, and alongside Matt and Myles, will be moving onto Level 3. A new team from Joseph Ash will also start Level 2. (Back row left to right: James Crookes, Matthew Phillips, Dean Holland, Matt Green. Front row left to right: Mark Payne, Myles Durward, Dave Foster (In-comm trainer), Wayne Smith)

Congratulations to all our team members endeavouring to learn new skills, improve our plants and further their careers. The commitment to learning is great! A special congratulations to Matt and Myles too.

Thanks for such a great event In-Comm!

Welcome to the latest Joseph Ash Galvanizing newsletter. Hot off the press today!

To read a copy click here.

To receive a copy of the newsletter in your inbox each month, please subscribe. Simply scroll to the bottom of the page and look for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too! Please feel free to get in touch with your news, and we’ll try to feature it.

Hot dipped galvanized steel for a new clubhouse at Harlesden Community Garden Project

In 2013, an open space and playground for the local community in Harlesden had become an area that was uninviting and known for anti-social behaviour. A community consultation was held to see how to improve the land. As a result, an organisation called the Friends of Harlesden Town Garden (FHTG) was created (in partnership with Crisis Brent and Brent Council) to improve the parkland with a new play area for children, a green lawn and wild flower area, a multi-use games area and raised bed allotments. As part of the project, FHTG also wanted to build a community Clubhouse. A number of volunteers, businesses, charities and educational facilities – including Joseph Ash Medway, Storp Weber Architects, the Bartlett School of Architecture, Lafarge, F.H. Brundle, and Lathams – stepped in to help with construction and funding.

The Clubhouse – which is currently under construction – will sit at the heart of the new community garden. Designed by local Brent Architects Storp Weber – as part of an on-going research and community outreach activity at the Bartlett School of Architecture – the building will act as a central hub where visitors and gardeners can go for tea and biscuits or conversation. It will also be used as a multi-functional, eco-friendly venue for workshops, events and meetings.

The main shell of the Clubhouse is a shipping container surrounded with a steel frame and timber panelled perimeter. Lafarge provided the insulation, Lathams provided the timber, and F.H. Brundle provided the steel frame which Joseph Ash Medway was only too happy to galvanize.

Joseph Ash Medway collected 72 pieces of steel in total, collectively weighing 842kg, from the Bartlett School of Architecture, galvanized it and delivered it to Harlesden. The hot dip galvanized finish will protect the steel from the elements – rust and erosion – for the next 25 years.

Tim Palmer at Joseph Ash Medway said: “The Harlesden Community Garden Project is a great initiative where people can work hard, play hard, exercise, learn new skills, improve their area, and meet new people. The Clubhouse acts as a focal point for the garden and we were happy to donate our services when the School of Architecture approached us. It has been great to work in partnership with Storp Weber, Lafarge, Brundle Steel, Lathams and the students at the University. It’s also amazing to see what can be achieved when many groups – communities, organisations, businesses – pull together.”

The Clubhouse project has been taking shape and is due to be completed in July. The groundworks will then be added, and the grand opening should take place in August or September. We’ll keep you posted on future developments and share posts on the Joseph Ash Instagram account.

___________________

You can also read about the project on the Bartlett School of Architecture webpage.

There is also a short film produced by Saint Gobain Isover about the building.

Certificate in Leadership and Management for team members at Joseph Ash Galvanizing

We’re pleased to announce that five members of our team across five of our plants have recently completed the Certificate in Leadership and Management, Levels 3 and 5.

The course is designed for middle managers to develop and strengthen their skills including management and leadership, managing team and individual performance. It also enables them to become stronger leaders by discovering new and innovative ideas and creative approaches to business management.

The five team members are:

- Tracie Lockley – Level 5 – Deputy Divisional Manager, Joseph Ash Telford

- Sukhwinder Singh – Level 5 – Deputy Divisional Manager, Joseph Ash Walsall

- Mark Payne – Level 5 – Divisional Manager, Joseph Ash Chesterfield

- Rob Nelson – Level 5 – Divisional Manager, Joseph Ash Bilston

- Kevin Williams – Level 3 – Divisional Manager, Joseph Ash Bridgend

The course was conducted by Professional Development Training Ltd, in Birmingham.

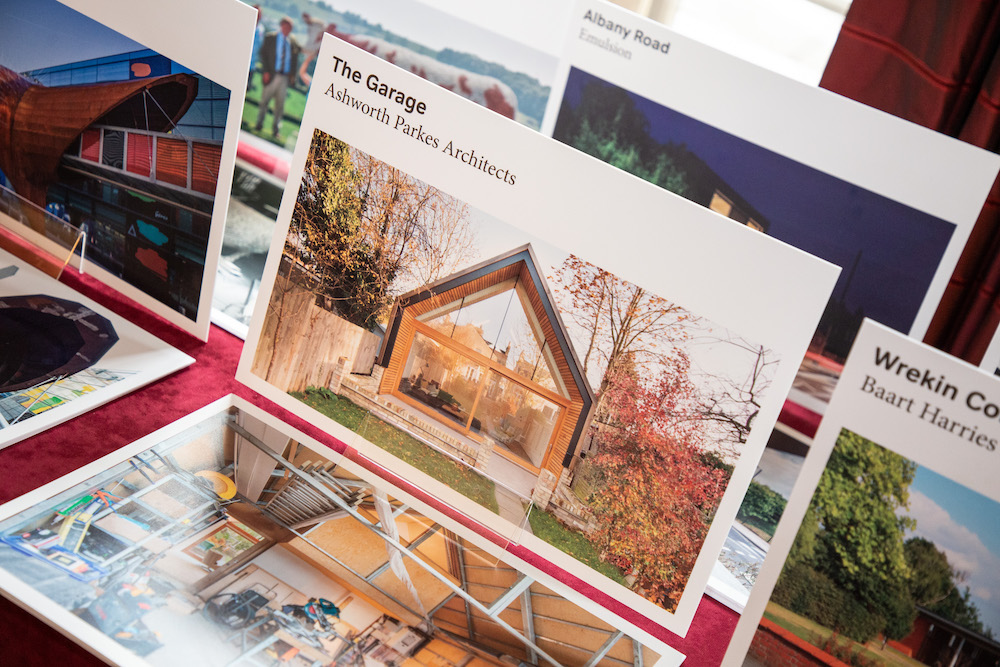

Last Friday we attended the annual Galvanizers Association Awards – more affectionately known as The GAGAs. It was a great event, held at the Royal Aeronautical Association HQ in London.

The GAGAs are a chance for fabricators, constructors, engineers, architects and artists to showcase a project they have worked on in involving galvanizing. They do this by submitting an entry into one of the following categories:

- Galvanizing in Architecture

- Galvanizing in Engineering

- Galvanizing in Detail

- Sustainability Award

- Duplex Awards.

The Galvanizing Association received many amazing entries and it was great to attend the awards and see the details of each shortlisted project.

It was also a special year for the Galvanizers Association as they celebrated their 25th year of hosting the awards.

The winners of the 2019 awards are as follows:

- The Rising Path in Cambridge by the chadwick dryer clarke studio who won the Galvanizing in Architecture Award

- Conservation of Catrine Weir by Addison Conservation + Design who won the Galvanizing in Engineering Award

- Palas Cinema in Galway, by dePaor who won the Galvanizing in Detail Award

- Hauxley Wildlife Discovery Centre by Brightblue Studio who won the Sustainability Award

- Nine Elms Thames Path Pavilion by Studio Weave who won the Duplex Award.

A few extra awards/commendations were also given out:

- Jailmake received a Special Mention for their RHS Rootbench which featured at the 2017 Chelsea Flower Show

- Stephen Taylor Architects were Highly Commended for the Cadix Housing project in Antwerp

- The Eden Project by Grimshaw Architects also won the highly prestigious ’25 Years Winners’ Winner Award’.

Further information about each of the winners plus the projects is available here.

If you are interested in entering the 2020 GAGAs, click here.

Thank you to the Galvanizers Association for another wonderful event!

Welcome to the latest Joseph Ash Galvanizing newsletter. Hot off the press today!

To read a copy click here.

To receive a copy of the newsletter in your inbox each month, please subscribe. Simply scroll to the bottom of the page and look for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too! Please feel free to get in touch with your news, and we’ll try to feature it.