A new bath at Joseph Ash Walsall

Joseph Ash Walsall has recently had a new galvanizing bath installed at the plant to replace the previous kettle.

The new Pillings Kettle bath is 60mm in thickness – 10mm thicker than the previous bath – which should give the plant an extra 2-3 years on top of its normal longevity.

A new kettle is a large investment, so it’s good to be able to demonstrate our commitment to our employees, to show that we’re in this business for the long-haul, thereby providing the job security they deserve, as well as confirming that we are able to make the necessary investments to ensure a safe, lasting operation for years to come.

The installation

Whilst all Joseph Ash Galvanizing plants normally close down at Christmas to give team members a well-earned break during the festive period, Joseph Ash Walsall employees continued to work to manage the installation of the new bath. Team members – including the Walsall team, Protherm, Zinco and Julian Cox – worked tirelessly throughout the Christmas break to ensure the project was a success.

Charlie Singh, Walsall Divisional Manager said: “The timescale was short and demanding for all concerned, but with all the necessary logistical efforts being planned down to a tee, the team were able to ensure that project was completed on time, and the plant was able to open for business as usual on 2nd January. This lives up to our values, promises and commitment to our customers, demonstrating that we can provide a service all year round!”

Well done to the team at Walsall for making this happen. An amazing effort!

Here are some photos of the bath installation. You can see more on our Facebook account.

Ray Rubenis retires from Joseph Ash after 37 years

Whilst looking on a Birmingham history chat room a few days ago we came across some text about the origins of Joseph Ash Galvanizing. One of historians in the forum stated that in the 1950s people used to queue to try and get a job at Joseph Ash Galvanizing, and once they had a foot in the door, it was a job for life with good pay and good experiences. We think this still rings true in more modern times, as we’ve just celebrated the retirement of a valued member of staff – Ray Rubenis – who has left the Company after 37 years’ service.

Ray started working at Joseph Ash Telford in 1982, starting out on the shop floor. From then on for the next 21 years, the Telford branch allowed Ray the opportunity to work his way up through Jigging to Dipping. In 2003, Ray moved to the maintenance department where he could also put his excellent fabrication skills to use. He spent another 11/12 years in this department ensuring any improvements/repairs were completed to keep the plant up and running.

In mid-2012, due to the economic situation at the time across the UK, Ray was facing redundancy. He did not want to leave the Company and he said, “the Walsall Branch came to the rescue and offered me a vacant position within their team, where I was able to work happily until my retirement”.

During Ray’s time at Joseph Ash Walsall he fabricated, repaired and completed general maintenance for the plant working with great support from a fantastic team. He said: “I worked at Joseph Ash for the best years of my life, totalling 37 years. I was extremely lucky to have found a career and home at both their sites and leave with only my best wishes to all the colleagues that I worked with during this time.”

Ray is now looking forward to spending his retirement looking after his grandchildren more often, going away with his caravan in tow whenever (and as often!) as he can, and completing all the jobs he’d been putting off over the years in his home “and of course whatever my wife would like me to do!”.

Congratulations on your retirement Ray. It’s been great having you as part of the Joseph Ash family for nearly 40 years. Enjoy your well-deserved retirement and come back and see us sometime!

First photo left to right: Osmond Crosdale (Maintenance Manager), Charlie Singh (DM Walsall), Ray Rubenis, Sukwinder Singh (Deputy Divisional Manager)

Second photo left to right: Gerry Green (Group Operations Director) and Ray Rubenis

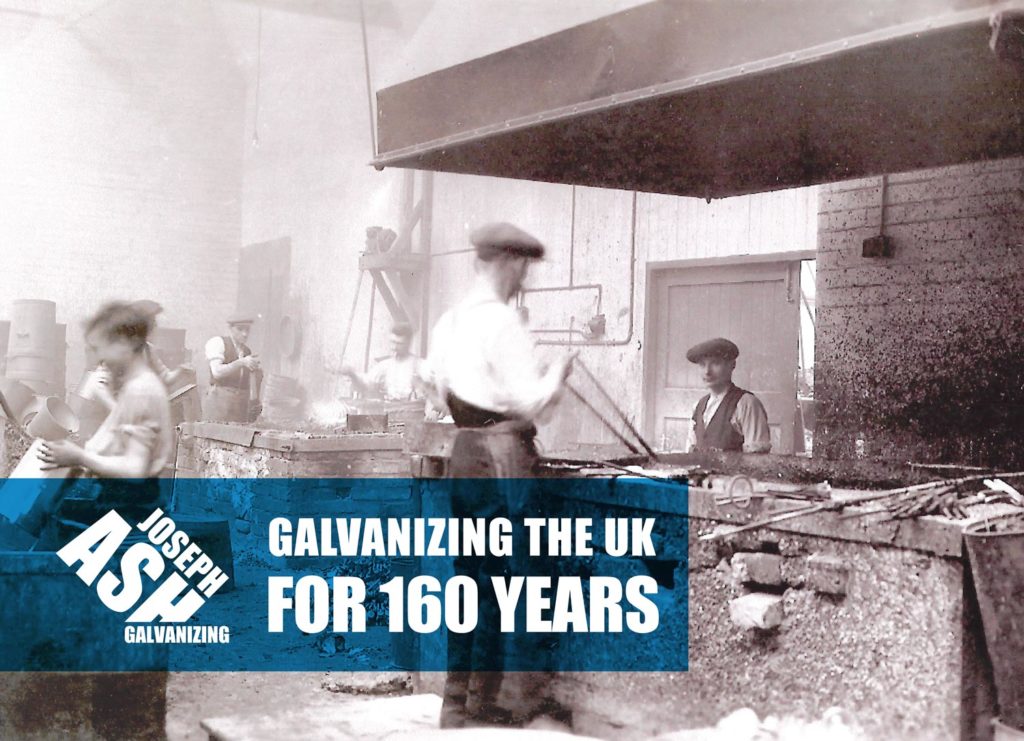

Joseph Ash Galvanizing was set up by Joseph Ash – the son of a Birmingham Chemist – in 1857 and this photo is from one of our original plants in Birmingham in the early 1900s.

For over 160 years Joseph Ash Galvanizing has been in business. From bridges in the north to skyscrapers in the south… From roads in the east to railways in the west, we’ve seen it all and hot dip galvanized it all. We’re proud to galvanize the UK.

If you have any metal finishing needs – hot dip galvanizing, powder coating and shot blasting – contact us today. We’d love to help.

We’re pleased to announce that Joseph Ash Galvanizing’s Medway plant has again met the bronze level requirements of the Fleet Operator Recognition Scheme.

Medway’s accreditation with FORS has just been renewed.

The Fleet Operator Recognition Scheme (FORS) is a voluntary scheme that covers all aspects of vehicle emissions, fuel efficiency, economical operations and safety.

It provides peace of mind to vehicle operators that legislative requirements are being met. It also enables vehicle operators to know they are helping to increase efficiency, win work, and reduce costs.

Finally, it enables operators to know they are becoming safer and greener.

Thank you to the FORS team for assessing us. Thank you also to the team at Joseph Ash Medway who worked hard to receive the award.

Welcome to the latest Joseph Ash Galvanizing newsletter. Hot off the press today!

To read a copy click here.

To receive a copy of the newsletter in your inbox each month, please subscribe. Simply scroll to the bottom of the page and look for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too! Please feel free to get in touch with your news, and we’ll try to feature it.

A few weeks before Christmas our Joseph Ash Bilston plant played host to a group of six students – aged 17 and 18 – from a local technical college, the Ormiston SWB Academy.

As students at the Academy are currently learning about metal surface finishes, including hot dip galvanizing, Daniel Brittle (the Director of D&T at the school) requested the visit, knowing it would be beneficial for them to see some of the treatments in action. We couldn’t agree more!

On December 13, the students and teacher visited us and were shown around the plant by Rob Nelson (Divisional Manager). They were able to see the galvanizing process in action and hear about some of the procedures we go through to ensure a good, clean finish for steel. Rob also explained the importance of health and safety at galvanizing plants because of the heavy machinery and lifting equipment, as well as the molten hot zinc used to galvanize the steel.

After the visit Daniel Brittle commented: “It was fantastic to see the plant in action, specifically the processes you go through and the types of products you galvanize. The students gained a great deal from the visit.”

Rob Nelson said “It was enjoyable showing the students around the plant. Galvanizing is used to protect steel for street lights to motorway barriers, bridges to railway infrastructure, flooring to fencing, and buildings to agricultural structures, so it’s great to highlight its importance and show the types of steel products we treat. We were also pleased to help the students increase their knowledge by turning the things they might read about in textbooks to reality.”

Ormiston SWB Academy: thank you for visiting us. It was a pleasure!

25 years ago, in 1993, ‘Jurassic Park’ and ‘The Firm’ showed at the cinema; ‘Seinfeld’, ‘Roseanne’ and ‘Murder, She Wrote’ were amongst the most popular TV shows; Meatloaf spent over a month as UK number one for ‘I’d Do Anything for Love’; and Pete Sampras and Steffi Graf won Wimbledon. Also, in this year – in Joseph Ash Galvanizing related history – Pauline Alcide joined our team!

Pauline started her career at Joseph Ash in the Head Office as a Payroll Clerk. Fast forward seven years to 2000, and she was promoted to Assistant to the Accountant. In 2003 she also took on the extra responsibility of managing the payroll for the company.

Pauline reports to Richard Hall, the Finance Director for the Joseph Ash Group, and can be seen in the photo being presented with some flowers from Steven Hopkins, Managing Director.

‘Loyal’, ‘honest’, ‘funny’ and ‘very friendly’ are the words that spring to mind when we think about Pauline, so we are lucky to have her working with us.

When Pauline isn’t working, she loves to dance, enjoying salsa nights with her husband every week.

Congratulations on reaching your 25-year anniversary Pauline! A great achievement.

Happy New Year to all our customers and contacts!

We hope you had a lovely and restful Christmas break. Here’s to a great 2019!

End of year message and Season’s Greetings from Steven Hopkins, MD at Joseph Ash Galvanizing.

Dear Customers,

As we come to the end of 2018, I think we can agree it has been an unforgettable year, given the tsunami of politics that has broken over us and the sheer amount of energy expended by all parts of society in trying to solve the unsolvable with Europe. It seems to me that there is a hugely wide spectrum of opinions, all passionately held by significant numbers of people and my guess is that, whatever the outcome, we will still be hearing arguments for decades to come.

Remarkably, the economy appears little affected. There has undoubtedly been a slow-down in major construction projects, perhaps deferments due to uncertainty by investors, in part offset by badly needed housebuilding. However, the galvanizing industry’s volumes are only slightly down compared to 2017 levels and I doubt that galvanizing has lost any market share to paint, which probably reflects the activity in our customers’ workshops too.

Similarly, our customers in the main seem positive about the next few months at least, despite the deadlines fast approaching for Brexit decisions and enactment, and concerns over possible border delays. For our own part, we have sought and obtained assurances from our suppliers that our inputs will not be affected by any outcome.

In other news, we’ve also had an unforgettable year in terms of the work we have taken on and the construction projects we’ve been involved in, and we’d like to thank you for sending them our way. Everything from steel barriers for the new Mersey Gateway Bridge to galvanized pressure vessels for the UK’s two new aircraft carriers, Andy Scott’s new ‘Canter’ sculpture to Luke Perry’s Queen Aethelflaed statue, and countless steel products used across the UK’s roads and transport network. We’ve even been involved in a recent project with REIDSteel to help rebuild a school destroyed by 2017 hurricanes on the British Virgin Islands.

We’ve also celebrated some internal achievements, namely long-time service anniversaries for many of our employees, renewed memberships and accreditations with significant industry bodies, attendance at a number of trade shows and exhibitions, and the joy of networking with some of you at various events held by organisations such as the British Constructional Steelwork, the Rural and Industrial Design and Building Association and the Galvanizers Association.

As we sprint towards 2019, we look forward to a bright year ahead and to continuing our partnership with you, hopefully hitch-free and at good levels, throughout the year and beyond. Before we get there though, I wish you, your families and your colleagues the happiest of Christmases and a very healthy and prosperous New Year.

Regards,

Steven Hopkins

Joseph Ash joins forces with REIDSteel and steel suppliers to rebuild hurricane devastated school.

Steelwork is on a 4,000 mile journey from Dorset to the Caribbean for the reconstruction of a primary school, devastated by hurricanes Irma and Maria last year.

Christchurch-based John Reid & Sons Ltd (REIDsteel) is leading a consortium of businesses in the UK which have joined forces to help rebuild the Enis Adams Primary School in the British Virgin Islands.

The company, which has exported to the Caribbean for more than 30 years, has rallied its suppliers to provide support free of charge, in kind or at a discounted rate to the total value of £35,000.

The suppliers are Tata Steel, National Tube Stockholders, Joseph Ash Galvanizing, Euroclad, Ayrshire Metal Products, BAPP, Powell Gee & Co Ltd, Kestrel Liner Agencies and Meachers Global Logistics.

The main contractor in Tortola, Newton Construction Co Ltd, with whom REIDsteel has worked for 34 years, is leading the construction work and will erect the steelwork.

Virgin Islands businessman Peter Haycraft, who was a longstanding client of REIDsteel with his former business Road Town Wholesale, has pledged $1m of his own money for the school reconstruction to help the local community.

REIDsteel – whose specialities include disaster-resistant buildings – designed and manufactured the steelwork to withstand any future hurricanes and to give something back to the islands.

Now four 40’ cargo containers full of steel work are being shipped across the Atlantic for the project on the island of Tortola, with three more to follow in the coming months.

REIDsteel commercial director Tim Cook said: “We have built strong personal and professional relationships over many years in the Caribbean.

“It was terrible to see the damage wreaked by the hurricanes last year so we’re very grateful to Peter Haycraft for giving us the opportunity to help him give something back to Tortola.

“Our thanks to our suppliers and business associates who rallied around immediately. It is great to see the first shipment depart and we’re looking forward to the school rising from the ashes.”

Others involved in the project are architect AEMC Architectural Services, Civil Engineer AEC Consulting Engineers Ltd, Electrical Barry’s Electrical Services, Reliable Plumbing, S & D Security, and the British Virgin Islands Ministry of Education and Culture.

Hesketh Newton, managing director of Newton Construction Co Ltd, said: “We have made good progress so far and the new school will really begin to take shape with the arrival of the steelwork.

“As a local family-owned business of 40 years, we’re very pleased for the opportunity to give back by supporting this project.”

Peter Haycraft said: “I have worked closely with REIDsteel and Newton Construction Co Ltd for many years.

“I am delighted that we are all able to do something for the community following the hurricane and look forward to the school children arriving on the first day of term.”

The first ground has been broken for the reconstruction of the school, which is due to open in September 2019.

It will have state of the art classrooms with smart boards, computer suites, library, solar panels, wheelchair access and therapeutic suite for instruction of specially gifted kids.

REIDsteel, which celebrates its centenary next year, designed the building to withstand 185 mile per hour winds and earthquakes based on Unified Building Code Occupancy Category III and IV.

All of REIDsteel’s 26 buildings in the British Virgin Islands survived with only superficial damage after the hurricanes which lashed the region last year.

REIDsteel has provided design and manufacturing services on a not for profit basis worth over £30,000.

Tata Steel is helping with the supply of ComFlor® floor decking and providing Colorcoat® pre-finished steel including Colorcoat Prisma®, whilst Cardiff based Euroclad are giving finished roof systems.

Thirsk-based National Tube Stockholders has given steel tube and steel hollow sections, Joseph Ash Galvanizing is hot-dip galvanizing the structural steelwork and Ayrshire Metal Products has given secondary steel – cold rolled purlins

Barnsley-based BAPP has supplied industrial fasteners and bolts, Powell Gee of Shrewsbury has supplied fixings for floor decking and the external cladding envelope.

Kestrel Liner Agencies, a global Caribbean shipping specialist which offers weekly sailings from more than 145 ports to the Caribbean basin, is helping with shipment and Meachers Global Logistics with shipping services.

Andy Thorne, Kestrel group chairman, said: “In the immediate aftermath of Hurricane Irma and Maria we were able to get people on the ground and provide specialist logistical and financial support to the region.

“A year on we are delighted to team up with our customers and partners to help rebuild the school. Our mission statement says it all, ‘Global reach – local focus’.”

REIDsteel has the capacity to design, manufacture and supply entire steel buildings – including their cladding and glazing – anywhere in the UK, Europe and across the World. It has exported to more than 140 countries to date.

Visit www.reidsteel.com for more details.