June 2017 newsletter

The June edition of the Joseph Ash Galvanizing newsletter is here. Hot off the press!

To read a copy click here.

Read about our new ‘Design Right for Galvanizing’ video, which is perfect for pre-galvanization design hints and tips; how we hot dip galvanized the steel for a new public benches at the Chelsea Flower Show; our plant open days in September; and our new ‘Venting Tips for Hot Dip Galvanizing’ poster.

If you would like to receive a copy of the newsletter in your inbox each month, please subscribe by scrolling to the bottom of the page and looking for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too, so feel free to get in touch with your news, and we’ll try to feature it.

Galvanized steel used in benches at the Chelsea Flower Show 2017.

In 2016 JAILMAKE was commissioned by the RHS to design new benches for the 2017 Chelsea Flower Show. As part of the project, JAILMAKE used the services of Premier Galvanizing (a division of Joseph Ash Galvanizing) to galvanize the steel.

JAILMAKE is a London-based design 3D practice. The company describes itself as a collaborative practice of 3D designers and engineers who design and make, across all scales and typologies. With a wide-ranging portfolio of interesting and unusual projects under their belt, the RHS (the Royal Horticultural Society) decided the company would be a good fit to build a series of benches, for event-goers at the 2017 Chelsea Flower Show. The team at JAILMAKE were happy to take on the project.

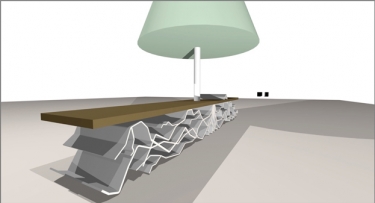

The RHS ordered six benches in total, and after a series of sketches, meetings and discussions, the final design looked like the drawing to the right.

Each bench would be 4m long, made from folded steel, with a wooden structure (made from European Oak) on top, where people would sit. They would be delivered in two parts to the event, and constructed on site, with the wooden structure laid across the top.

Being commissioned by the RHS, for the Chelsea Flower Show is an honour and JAILMAKE wanted to do a great job. In a project like this, a large part of ‘doing a great job’ not only revolves around the aesthetics and unique design, but also around the quality of materials, the finish, and the health and safety – i.e. ensuring the seats would be safe for members of the public to sit on.

To ensure the steel would be perfect, JAILMAKE contacted Premier Galvanizing to talk to them about treating the steel with a hot dip galvanized finish. Because the galvanizing process involves submerging the benches into boiling hot baths for hours, cleaning off any impurities from the steel and then submerging again, JAILMAKE had a concern about any potential distortion, as some of the steel plate in the structure was only 2mm thick. Premier Galvanizing were confident they could do a good job, and fully meet JAILMAKE’s specification and expectations.

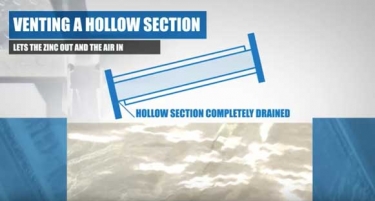

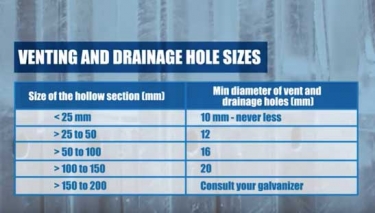

As part of their service, Premier Galvanizing offered to visit JAILMAKE’s London studio to inspect the steel before the final fabrication work was completed. This proved invaluable because the Premier Galvanizing team members realised the steel would require some additional venting and drainage points.

When it comes to galvanizing, the correct venting and drainage can be the difference between a poor galvanizing finish, and a finish with premium quality.

Premier Galvanizing could look at the steel, and then suggest slight changes to the technical (not the aesthetic) design so that JAILMAKE would receive the best possible outcome after the steel had been dipped into the zinc galvanizing bath.

Once the slight modifications had been made, Premier Galvanizing dipped the steel at their plant in Corby. JAILMAKE took some pictures of the benches being hot dipped galvanized, which can be viewed to the right.

The steel for the benches was delivered to Premier Galvanizing on 9 May – just a few weeks before the flower show began. Premier Galvanizing carried out their service and returned the steel to JAILMAKE.

Two days before the Chelsea Flower Show 2017 began, JAILMAKE put the benches in place, laid the oak, and applied any finishing touches. A few days later the doors were open to the public, and the benches were there to be used, admired and enjoyed.

JAILMAKE were pleased to be commissioned for such a high-profile project. Premier Galvanizing was also immensely proud to work for such an interesting and innovative company, but to also be involved in such a prestigious event.

(Some of the photographs to the right by Ollie Hammick)

Design for galvanizing is important. Watch our latest Joseph Ash Galvanizing film to find out why.

We’re pleased to announce that Joseph Ash Galvanizing has just launched a new film. The video is titled ‘Design for Galvanizing’ and its aim is to help fabricators follow valuable advice for designing and fabricating steel, which will eventually result in a premium hot dip galvanized quality.

The film is centred around the idea that poor fabrication design will result in:

- Health and safety issues

- Poor coating quality

- Additional costs

- Low production

- Failure to meet delivery dates.

Whereas excellent fabrication design will:

- Prevent health and safety accidents

- Lower costs

- Improve production rates

- Ensure the fabricator receives galvanized steel with a premium quality galvanized finish.

The importance of ensuring steelwork is suitably designed for hot dip galvanizing is an integral part of the galvanizing process. The team at Joseph Ash Galvanizing would love to work with you at the design stage to avoid any issues that can occur because of poor design.

Watch the video for some handy hints and tips about venting. We’d also be happy to visit your fabrication shop and advise on venting requirements. We also offer personalised ‘design for galvanizing’ workshops, which we can carry out at your place of work.

Help us to help you achieve a quality hot dip galvanizing coating.

Read the May edition of the Joseph Ash Galvanizing newsletter. We’ve published it today!

To read a copy click here.

Read about the Gallagher Stadium at Maidstone United FC, and how we hot dip galvanized the steel for a new stand at the ground. You can also find out about spin galvanizing and powder coating, and see the new livery on our Joseph Ash Galvanizing trucks, in support of the Passchendaele Salute which will take place in November 2017.

If you would like to receive a copy of the newsletter in your inbox each month, please subscribe by scrolling to the bottom of the page and looking for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too, so feel free to get in touch with your news, and we’ll try to feature it.

REIDsteel and Joseph Ash Galvanizing have scored a winning goal in a project to construct a new 1,768 capacity stand at the Gallagher Stadium.

Maidstone United football ground – known as the Gallagher Stadium – originally opened its doors in July 2012. At that time, it had a capacity of 3,000 people and it was a welcome addition to the area, as Maidstone United FC could play their first match in their home town in 24 years.

Since 2012 the Club’s fortunes improved as they were promoted through the Leagues, to the National League. League promotions came with expensive requirements however, some which dictated that the Stadium increase its capacity for supporters and fans.

A recent capacity addition came in the form of a new North Stand, constructed by REIDsteel. The new stand can house an extra 1,768 ticket holders, which brings the stadium’s total capacity up to 4,200, making it eligible for the Conference Premier.

REIDsteel worked directly with Maidstone United FC to design, draw, fabricate and erect the £850,000 structure at the club’s Gallagher Stadium – including steelwork, cladding, 500m of handrails and disabled access ramps. The architect on the project was Arete Architects and the contractor was FM Conway.

The steel-framed standing terrace has been built behind one of the goals. It consists of 11 double standing rows, formed with non-slip metal decking supported by a series of steel rakers. The stand has a 11m-wide cantilevering steel roof structure, which includes a 1m-high facia for advertising.

The structure includes 81 tonnes of steel, all fully galvanized by Joseph Ash Galvanizing.

REIDsteel designs, manufactures and erects all types of steel-framed buildings and structures nationally and internationally, including commercial premises, aircraft hangers, stadiums, bridges, process plants and industrial units and has experienced rising demand from sports clubs worldwide for stands of varying size and capacity.

Over the years, they have called on the expert services of Joseph Ash Galvanizing, to protect their steel fabrications with a variety of metal finishing treatments, predominantly galvanizing.

Because REIDsteel fabricates many huge structures, the Joseph Ash Chesterfield plant quite often treats their steel. The plant is perfect for REIDsteel projects as it is centrally located in Derbyshire near the M1, and is also the largest Joseph Ash Galvanizing site with acres of space, enabling it to handle the biggest of projects including storage before and after galvanising.

Tim Cook from REIDsteel said: “Working on the Maidstone United football ground has been an exciting project, and it’s great to see the stand in use by the club’s many fans. We were also happy to work with Joseph Ash Galvanizing on the project. We have been using their metal treatment services for many years and have always been happy with the high quality and professional service they provide.”

Steven Hopkins from Joseph Ash Galvanizing said: ”As always, it has been our pleasure to treat REIDsteel’s fabrications. We have worked with the company for several years on projects ranging from bridges and warehousing in Africa to general structures and stadiums and sports venues in the UK.”

Read the April edition of the Joseph Ash Galvanizing newsletter. It’s hot off the press today!

To read a copy click here.

Read about the Passchendaele Salute 2017 that some of our Joseph Ash lorries will be providing transport for, our latest RoSPA Gold Award, the Lily Mae Foundation Golf Day, and 35 year’s service for Gerry Green in our head office.

If you would like to receive a copy of the newsletter in your inbox each month, please subscribe by scrolling to the bottom of the page and looking for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too, so feel free to get in touch with your news, and we’ll try to feature it.

Joseph Ash Galvanizing continues to support the Lily Mae Foundation at annual charity event.

On Friday 21 April Joseph Ash Galvanizing once again hosted guests at a charity golf day at The Belfry for a local stillbirth charity.

The Golf Day is organised every year by the Lily Mae Foundation – an organisation created to support parents and families affected by stillbirth or neonatal death.

Joseph Ash Galvanizing bought tickets for rounds of golf, seats at the evening dinner, and sponsored a hole. We also hosted many clients and partners at the event.

The Golf Day alone has raised £17,000 to help the charity.

If you attended the event, we hope you had fun and hopefully you’ll join us again in 2018.

To see photos of the event visit the Joseph Ash Galvanizing Flickr profile.

To find out more about the work of the Lily Mae Foundation, click here.

In April 2016 Joseph Ash Galvanizing published an article about the Passchendaele Salute 2017 – an event that will be held near Lille, France later this year, to commemorate the centenary of the end of the Battle of Passchendaele during World War One. (You can read the full article here.)

As time draws near – with only six months to go – we thought we’d highlight the event again by asking you to visit the Passchendaele Salute 2017 website.

“The Passchendaele Salute 2017, under the patronage of Ms Janice Charette, High Commissioner for Canada, will take place on the morning of 10 November 2017 at Fort de Seclin, near Lille in France. A Drumhead service of remembrance and a Salute of 100 rounds to commemorate the centenary of the end of the Battle of Passchendaele and honour the gunners.”

We’re pleased to say that John Slough of London (a client of Joseph Ash Galvanizing who refurbishes antique guns), will carry some of the guns that will be used in the Salute from the UK to France, on some of our Joseph Ash Galvanizing lorries.

The Passchendaele Salute 2017 will also raise money for a worthy charity called Combat Stress that provides free specialist and clinical treatment and support to ex-servicemen and women.

Keep a watch out on our website for further updates!

Joseph Ash Galvanizing picks up a prestigious RoSPA Award.

Joseph Ash Galvanizing is proud to announce that we are a GOLD winner for the RoSPA Health and Safety Awards 2017. We have achieved the Gold award in the prestigious annual scheme run by the Royal Society for the Prevention of Accidents (RoSPA).

The award will be presented during a ceremony at the Hilton Birmingham Metropole Hotel on Thursday, July 13, 2017. The award has been achieved during a special year for family-safety charity RoSPA, as it celebrates its centenary.

Through the RoSPA Awards scheme, which is open to businesses and organisations of all types and sizes from across the UK and overseas, judges consider entrants’ overarching occupational health and safety management systems, including practices such as leadership and workforce involvement. The awards are now in its 61st year.

Julia Small, RoSPA’s head of awards and events, said: “The RoSPA Awards are the most prestigious in the world of occupational health and safety, and held in high regard around the world, as winning one demonstrates an organisation’s commitment to maintaining an excellent health and safety record. Achieving the standard required is no mean feat.

“This is a special year in the history of RoSPA, and we congratulate all of our winners in this, our centenary year”.

The majority of awards are non-competitive and mark achievement at merit, bronze, silver and gold levels. Gold medals, president’s awards and orders of distinction are presented to organisations sustaining the high standards of the gold level over consecutive years. For the first time in 2017, the Patron’s Award has been presented to those organisations that have achieved consecutive gold awards for 25 years or more.

Competitive awards go to the best entries in 24 industry sectors including construction, healthcare, transport and logistics, engineering, manufacturing and education.

There are specialist awards for occupational health, environmental management and fleet safety, and excellence trophies for the best international, new entry, workforce involvement and organisation operating or based in Scotland. RoSPA’s top accolade is the Sir George Earle Trophy.

The headline sponsor of the RoSPA Awards 2017 is NEBOSH – the National Examination Board in Occupational Safety and Health – for the 12th consecutive year.

For more information about the RoSPA Awards visit www.rospa.com/awards.

Please note that all Joseph Ash Galvanizing plants will be closed during the Easter weekend. The plants will be closed from Good Friday to Easter Monday and will re-open on Tuesday 18 April 2017.

Have a great Easter weekend!

From all the team at Joseph Ash Galvanizing.