November 2016 newsletter

The November edition of the Joseph Ash Galvanizing newsletter is hot off the press today!

To read a copy click here.

Find out about a Remembrance Day statue we recently galvanized, a long-time service award for a Joseph Ash employee, as well as our Christmas opening hours.

If you would like to receive a copy of the newsletter in your inbox each month, please subscribe by scrolling to the bottom of the page and looking for the ‘Newsletter Sign-Up’ button.

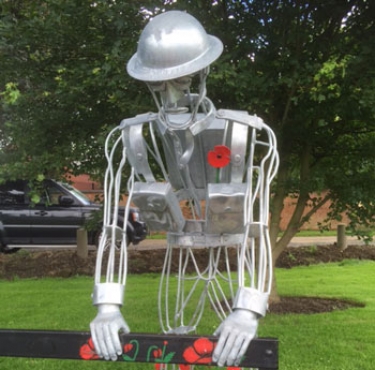

Tin Tommy sculpture, looking reflective at 2016 Remembrance Day Parade

On Sunday 13 November, the town of Immingham in North East Lincolnshire, held a Remembrance Day Parade at the Pelham Road War Memorial. The event was a fitting tribute to all soldiers who have lost their lives defending our country.

As part of the ceremony, a new statue stood at the War Memorial, leaning on a memorial seat covered in poppies. The statue was nicknamed Tin Tommy by local school children in the community, and he has become so popular that he even has his own Facebook page.

Tin Tommy was commissioned by the Barton Living Memorial Trust, who raised funds from the local council and communities. The aim of the Trust is “to educate the next generation about the World Wars and the sacrifices that so many made, and to keep the memory alive“.

When standing straight, Tin Tommy is a full-sized six foot high statue of a WW1 era British soldier, with red poppies painted onto parts of his frame. The bench that he leans upon has been designed to allow people to sit and “reflect on life, history and memory“.

Tin Tommy was fabricated by Hodson & Kauss, and hot dip galvanized by one of Joseph Ash Galvanizing’s divisions: Premier Galvanizing Hull.

Hodson & Kauss are expert fabricators who mainly fabricate bridges, walkways, fencing, staircases, and balustrades. Sometimes they are asked to fabricate unusal items such as Tin Tommy too. Hodson & Kauss have been using Premier Galvanizing Hull for all their galvanizing needs, for a long time. Premier Galvanizing are proud to have played a part in the construction of such an important statue.

(More photos of Tin Tommy can be found on the Joseph Ash Galvanizing Flickr site.)

In 1985 Gorbachev became the de facto leader of the Soviet Union, ‘Live Aid’ took the world by storm, Windows 1.0 was released, and ‘Back to the Future’ appeared at the cinema. At Joseph Ash Galvanizing, this is also the year that Mohammed Zamen joined our company! Fast forward three decades later and we’re pleased to report that Mohammed is still here, as part of the Joseph Ash family.

Mohammed joined Joseph Ash Walsall in 1985 and has worked in ‘Pickling’ roles within the plant, where incoming steel is pickled in dilute hydrochloric acid to remove all rust and mill scale from the steel surface prior to hot dip galvanizing.

He is a popular member of the team, and, as stated by Charlie Singh at Joseph Ash Walsall, “Mohammed has been very hard working, a loyal employee and an example to all”.

Steven Hopkins – Joseph Ash Galvanizing’s MD – and some Walsall colleagues were recently on hand to give Mohammed a long-time service award.

Three decades is a great achievement.

Well done Mohammed!

Read the October edition of the Joseph Ash Galvanizing newsletter. It’s hot off the press today!

To read a copy click here.

Find out about our upcoming Open Days at our Chesterfield plant later this week, recent sculptures of dragons that we galvanized for Phoenix Forge Ltd, and details about the winners of the Structural Steel Design Awards 2016.

If you would like to receive a copy of the newsletter in your inbox each month, please subscribe by scrolling to the bottom of the page and looking for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too, so feel free to get in touch with your news, and we’ll try to feature it.

Awards for efficiency, cost effectiveness, aesthetics, sustainability and innovation.

On Wednesday 5 October 2016, the 48th Structural Steel Design Awards took place at the Museum of London. The awards, hosted by the British Constructional Steelwork Association (BCSA), in conjunction with Steel for Life, celebrated the UK excellence of the steel construction industry.

The competition was open to completed steel based structures in the UK or overseas that had been built by UK or Irish steelwork contractors, and the five winners were:

- London Olympic Roof Conversion

- Thames Tower Redevelopment, Reading

- Etihad Stadium

- Harlech Footbridge

- The Memorial Spire, International Bomber Command Centre, Lincoln.

President of the BCSA, Wendy Coney said: “Tonight’s shortlist demonstrates that steel is … the structural material of choice for schools, offices, sports stadia, power generation facilities, footbridges, and a wide range of other structures. Much has changed since our 2015 Awards ceremony. It has been a tumultuous year for UK steelmakers. But the supply of structural steel was unaffected and confidence in steel as the framing material of choice has been maintained.”

Congratulations to the winners!

The bread and butter of Joseph Ash Galvanizing’s work is centred around galvanizing steel used in transport, farming, construction and infrastructure. We do this for fabricators, fencing and agricultural manufacturers, and large structural steelwork companies. Every so often however we also receive a project from a steel sculptor. The works are unusual, intricate and detailed and we deem it an absolute pleasure to become a part of the sculptor’s artistic process.

The most recent pieces of art that came onto our yard at Joseph Ash Bridgend were two huge steel dragons, fabricated from Phoenix Forge Ltd, a bespoke metalwork and blacksmith’s business based in Carmarthen, South Wales.

Phoenix Forge generally specialises in traditional and contemporary metalwork, producing a wide range of hand forged artistic, decorative and functional ironwork including: gates, railings, balconies, public artwork, curtain poles, fireplace tools, restoration and bespoke commissions. They have also sculpted a number of dragons too!

Two such dragon installations were recently sent to Joseph Ash Bridgend: a dragon curled around a lamp post; and a sleeping dragon.

Will Holland from Phoenix Forge said:

“The dragon lamp post sculpture was vast with a wing span of approximately 6-7 feet and a nose to tail of about 9 feet, however the sleeping dragon was a lot larger, but curled up on a rock with a diameter of 6 feet.”

After spending over 300 man hours, over a period of six weeks, to make each dragon, Phoenix Forge asked Joseph Ash Bridgend to hot dip galvanize both sculptures. Galvanizing is an important finish for outside sculptures such as these as the treatment protects the steel from atmospheric conditions and rust.

It is important for blacksmiths such as Phoenix Forge to be able to trust suppliers, especially with one-off pieces of art. Holland said the following about Joseph Ash:

“We send all of our hot dip galvanizing work to Joseph Ash Galvanizing. We’ve been using them for a couple of years and they do an excellent job for us. They are incredibly helpful, reliable and take good care of our work – which is so important given the amount of man hours it takes us to fabricate a sculpture.”

The dragon climbing the lamp post sculpture was commissioned by a private collector in Shropshire who has bought several similar sculptures from Phoenix Forge over the last few years. The artwork has now been installed outside the client’s private residence.

In contrast the sleeping dragon – which is made up of over 5000 individual steel scales – was fabricated as a show piece for Phoenix Forge’s display at the 2016 Royal Welsh Show at the National Botanic Gardens in Wales. The sculpture is currently on loan at the Gardens until a permanent home is found.

To see a video which shows how Phoenix Forge make dragons, watch YouTube here.

We’re looking forward to receiving more projects from Phoenix Forge in the future!

The September edition of the Joseph Ash Galvanizing newsletter is hot off the press today!

To read a copy click here.

Find out about our upcoming Chesterfield plant Open Day, as well as our participation at UK Construction Week at the NEC in Birmingham. You can also read about the Galvanizers Association’s new website, and the 48th Structural Steel Design Awards.

If you would like to receive a copy of the newsletter in your inbox each month, please subscribe by scrolling to the bottom of the page and looking for the ‘Newsletter Sign-Up’ button.

Structural Steel Design Awards – Wednesday 5 October 2016.

On Wednesday 5 October, the 48th Structural Steel Design Awards will be taking place in London, and Joseph Ash Galvanizing will be in attendance supporting all the winners and runners-up.

Hosted by the British Constructional Steelwork Association, in conjunction with Steel for Life, the awards celebrate the UK excellence of the steel construction industry, with particular reference to cost effectiveness, aesthetics, efficiency, innovation and sustainability.

The competition was open to completed steel based structures in the UK or overseas that have been built by UK or Irish steelwork contractors.

In July 2016 the BCSA announced that out of the many entries they had received, the shortlisted projects had been narrowed down to 21. The winners will be chosen from the following list:

- Kiosk and Shelter, Bournemouth Pier Approach

- Leeds Station Southern Entrance, Leeds

- Thames Tower Redevelopment, Reading

- Energy from Waste Plant, Fengate, Peterborough

- Whyke Horizon Footbridge, Chichester

- South Bank Tower, London

- Energy from Waste Facility, Ardley

- Plant-support Structures, Ferrybridge Multifuel 1

- New Watford Market, Watford, Hertfordshire

- Information Age Gallery, The Science Museum, London

- The Diamond Engineering Building, Sheffield University

- The Memorial Spire, International Bomber Command Centre, Lincoln

- Sports Hall & Sixth Form Centre, Channing School, London

- London Olympic Roof Conversion, London

- South Stand Expansion, Etihad Stadium, Manchester

- University of Cambridge Primary School, Cambridge

- Harlech Castle Footbridge, Gwynedd

- Lagan Weir Pedestrian and Cycle Bridge, Belfast

- Strabane Footbridge, Co Tyrone

- 6 Bevis Mars Roof Garden, London

- Landrover BAR Americas Cup HQ Building, Portsmouth

Details about each of these projects – as well as related images – can be seen on the Steel Construction website.

Further details about the event in general can be also be viewed in this excellent video made by the BCSA.

The Awards event is set to be a great night, and we’ll report on the winners after they have been announced.

Good luck to all the shortlisted finalists!

Read the August edition of the Joseph Ash Galvanizing newsletter. It’s hot off the press today!

To read a copy click here.

Find out about our upcoming participation at UK Construction Week at the NEC in Birmingham, developments and extension plans at our Medway plant, and further details about the winners of the GAGAs 2016.

If you would like to receive a copy of the newsletter in your inbox each month, please subscribe by scrolling to the bottom of the page and looking for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too, so feel free to get in touch with your news, and we’ll try to feature it.

The July edition of the Joseph Ash Galvanizing newsletter is hot off the press! To read a copy click here.

Find out about our new powder coating colour swatch page, our upcoming participation at the Surface Materials Show at the NEC in Birmingham, developments at our Walsall plant, and how we have contributed to the build of a new biomass plant in Norfolk. You can also watch a video to see how Mabey Bridge Ltd erect their popular Compact 200 Bridge.

If you would like to receive a copy of the newsletter in your inbox each month, please subscribe by scrolling to the bottom of the page and looking for the ‘Newsletter Sign-Up’ button.

We’re always looking for interesting articles in the steel industry too, so feel free to get in touch with your news, and we’ll try to feature it.