The cost of corrosion

If your steel structures corrode, it’s not just financial costs you need to be aware of. It can also cost the environment and the health and safety of individuals.

We explore the costs associated with rusted steel on a personal and global level, and what can be done to mitigate these costs.

How much does rust cost to fix?

If left untreated, steel will inevitably corrode from elements such as oxygen, moisture, or chemicals. However, the speed at which steel corrodes can heavily impact global financial resources.

It is estimated that, globally, one tonne of steel will turn to rust every 90 seconds. Following a steady rate, that’s over 350,000 tonnes of steel in a year. This is a huge amount of steel to lose; it is estimated that corroded steel accounts for nearly 4% of Gross Domestic Product (GDP) lost every year.

From a global perspective, this has huge repercussions across many different sectors. Resources need to be used to manage, repair, or replace corroded infrastructure and equipment. This is a substantial financial burden, diverting funds away from other areas.

Costs to businesses

There are direct and indirect costs associated with steel corrosion for both individuals and businesses. The most immediate financial impact of corrosion is the cost of repairing or replacing damaged equipment and structures. This includes the cost of materials, maintenance and repair, and production downtime.

Indirect costs may include the inefficient running of machinery and other equipment due to corrosion. This can lead to higher energy consumption and increased operational costs.

Environmental cost of rust

It’s not just financial costs that are created from rusting steel – corroded steel can also harm the environment. CO² is emitted from corroded steel, with estimates of 1.6-3.2% of global CO² emissions being attributed directly to corroded steel.

If steel is particularly rusty, it may not be salvageable and safe to reuse. A new structure would need to be fabricated to replace it, but the steel fabrication process can be harmful to the environment. It has been estimated that new steel production accounts for 11% of all CO² emissions worldwide, contributing to climate change. Additionally, new steel fabrication requires raw materials, contributing to resource depletion and environmental degradation from mining and manufacturing processes.

Operational costs and safety risks

Machinery used in businesses across all kinds of sectors may become corroded, causing downtime, or slowed production lines. Downtime can also be extended to the unexpected failures of steel infrastructure, causing sudden downtime that can may impact finances and customer trust.

Health and safety can also be seriously compromised by corrosion; this may be especially true with load bearing steel infrastructure such as bridges and buildings. The failure of these fabrications can lead to catastrophic failures, endangering lives and causing serious injuries.

Save costs with hot dip galvanizing

There are many different costs associated with the corrosion process, but these can all be reduced by using a corrosion-resistant steel coating.

Hot dip galvanizing is a steel protection service that extends the lifespan of steel, allowing it to remain maintenance-free for multiple decades. In some circumstances, galvanized steel can last for over a century. Its extended lifespan for steel reduces financial impact by reducing the need for maintenance, refabrication, and recoating.

It’s not just financial costs you can save with hot dip galvanizing. It’s also a sustainable choice for coating steel, reducing environmental impact from logistics, refabrication, and emissions from corroded steel.

When you choose Joseph Ash Galvanizing, you can be sure you’ll receive a high quality finish from our friendly team that understands your unique requirements.

- We’ll collect and deliver your steel to our site ✔️

- Comprehensive technical support, guidance and assistance at every stage ✔️

- Fast turnaround times ✔️

- Hot dip galvanized to BS EN ISO 1461 standards ✔️

- Part of a circular economy ✔️

Steel protection services such as galvanizing have become modernised to fit into a sustainable future. However, are alternative coating technologies such as powder coating as sustainable? We explore what powder coating is, whether it fits into a sustainable future, and how it compares to traditional coating methods such as paint.

What is powder coating?

Powder coating is a steel coating method where coloured powder is electrostatically sprayed onto the surface of the metal. It is used as an alternative to paint, boasting many benefits where paint may fall short. As the powder is cured into the steel, it gives an extra layer of protection against corrosion and avoids chipping and damage. It can be used on top of galvanized steel to extends its lifespan even further.

Is powder coating sustainable?

Powder coating is more sustainable and environmentally friendly than paint in many ways.

Reduced VOC emissions

Traditional liquid paints often contain volatile organic compounds (VOCs), which can contribute to air pollution and have potential health hazards. Powder coating, on the other hand, releases negligible amounts of VOCs into the atmosphere during the application process.

Reduced waste

Powder coating generates less waste compared to liquid coatings. Excess powder can be reclaimed and reused, minimising the amount of material that ends up as waste. This is particularly beneficial in terms of resource conservation and waste reduction.

Increased longevity and durability

Powder coated finishes are known for their durability and resistance to corrosion. This longevity means there is a reduced need to maintain the steel with powder coating touch-ups. There is also less time associated with arranging for recoating the steel, which can cause extra emissions associated with transport.

The increased lifespan for steel also means that there is less need to fabricate new structures, reducing any environmental impact associated with steel fabrication. This helps powder coating form part of a circular economy.

Waste disposal

The already-minimal waste generated from the powder coating process is often less hazardous than waste from traditional paint processes. Disposal of unused powder coating material is generally easier and less environmentally impactful than the disposal of leftover liquid paint and associated solvents.

This, in combination with powder coating’s material efficiency, means that powder coating is a very sustainable choice.

All companies are responsible for sustainability

Although powder coating is more sustainable than paint, it’s important to note that the overall sustainability of a product also depends on factors such as the raw material sourcing, manufacturing processes, and end-of-life considerations.

The steel protection industry is still heavily reliant on transportation between plants and clients, impacting the environment. Fortunately, solutions are being implemented to minimise this, such as using hydrogenated vegetable oil in fleet vehicles, and making all forklifts electric. Company cars at Joseph Ash Galvanizing have made the shift to electric, too. Lastly, electricity comes from renewable sources, both on-site (from solar PV arrays) and externally (by using a renewable tariff with our supplier).

All companies – regardless of industry – also need to ensure they work with companies that share their sustainability goals. At Joseph Ash Galvanizing, all suppliers are vetted to include environmental accreditations and carbon reduction plans. We, in turn, are accredited to Environmental Management ISO14001 Standards.

Sustainable powder coating at Joseph Ash Galvanizing

Joseph Ash Medway is our one-stop shop facility for shot blasting, galvanizing, and powder coating.

- Protect steel against corrosion

- Collection and delivery service

- Fast turnaround times

- AkzoNobel approved supplier of powder coating

- A wide range of powder coating colours and finishes

The sustainability of galvanizing

Galvanized steel is an integral part of everyday life and is all around us. But how does its prevalence today affect the environment of the future?

We take a look at how galvanized steel fits into a circular economy, how the galvanizing process remains a vital and sustainable element within the metals sector, and how we can all play our part contributing to a sustainable future.

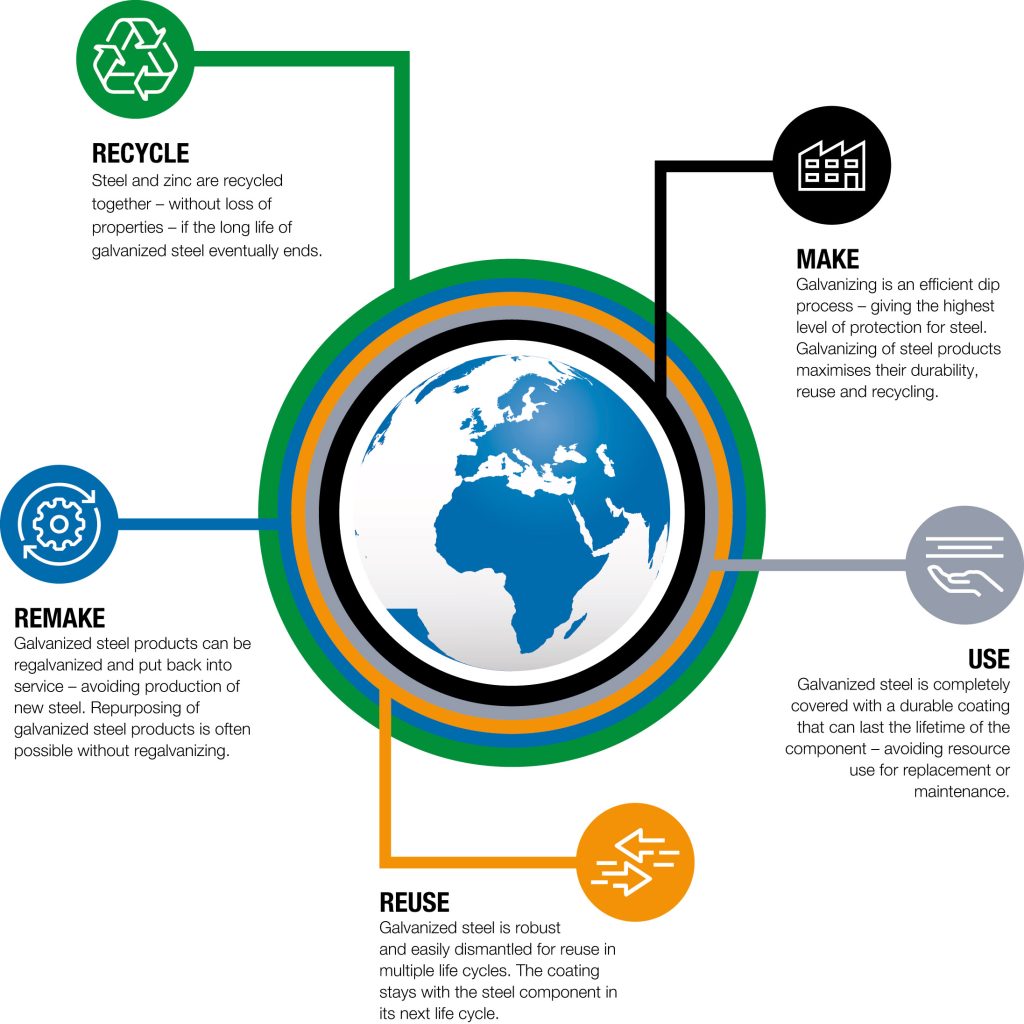

Galvanized steel in a circular economy

Steel must be repurposed if the world wants to move away from traditional use-throwaway-remake models. Fortunately, both the hot dip galvanizing process and the galvanized steel itself fit into a circular economy.

What is a circular economy?

Circular economy models of sustainability encourage materials to be made, used, reused, remade, and recycled. Galvanized steel, as a product, fits perfectly into a circular economy:

Make: Galvanizing companies have been able to reduce their emissions and energy expenditure thanks to modern technology and self-containment.

Use: Galvanizing steel ensures it can last a lifetime. This reduces resources and energy spent on maintaining the quality of the steel, such as transportation and manufacturing costs.

Reuse: The galvanized coating remains strong even after dismantling, allowing to be repurposed.

Remake: Galvanized steel products can be re-galvanized and put back into service, avoiding the production of new steel. Repurposing galvanized steel is often possible without regalvanizing.

Recycle: Steel and zinc are recycled together – without loss of properties – at the end of the galvanized steel’s long-lasting lifespan.

Sustainably modernising the galvanizing process

We’ve detailed how galvanized steel fits into a circular economy, but the galvanizing process itself has become sustainable, too.

In its traditional form, the galvanizing process was not particularly sustainable due to the high energy requirements, resource consumption, and emissions associated with the process. Fortunately, the galvanizing industry has come a long way to become more environmentally sustainable. Below are some of the ways that galvanizing sites have been adapted to promote sustainability.

Self-contained sites

Modern galvanizing plants are self-contained, with steel going in at one end and the final product coming out at the other. This reduces the release of carbon dioxide into the environment. Re-use of materials also happens during the galvanizing process and is not limited to the final product. Excess metal from the dipping process deposits back into the galvanizing bath. Additionally, zinc that oxidises on the surface is removed as ash and recycled; dross from the bottom of the bath is routinely removed and has a high recycling value.

Recycling and regenerating

Other process consumables, such as hydrochloric acid and flux solutions, have important recycling or regeneration routes. For instance, spent hydrochloric acid solutions are used to produce iron chloride for treating municipal wastewater. Closed-loop flux recycling is also used in many plants, and improved monitoring and maintenance of flux tanks reduce the volume of solids for disposal.

Wastewater management

Galvanizing uses low volumes of water compared to other coating technologies; any wastewater generated can be treated and reused, with only small volumes of stable solids requiring external disposal.

Energy efficiency and emission minimisation

The galvanizing industry has also set targets for energy efficiency and improved energy management. New technology has seen improvements in burner efficiency, bath lid efficiency, and reuse of waste heat to warm pre-treatment tanks.

Furthermore, abatement plants and low-fuming chemicals are utilised to minimise emissions to the atmosphere. Where captured, the waste from these emissions is completely recycled.

Sustainability is the responsibility of everyone

Sustainability in the galvanizing industry is not limited to the changes that take place around the bath itself; the industry is still heavily reliant on transportation between plants and clients. Therefore, it is important to assess environmental impacts as a whole, in addition to galvanizing-specific measures in the site itself.

Fortunately, new solutions are being implemented to minimise emissions, such as using hydrogenated vegetable oil in fleet vehicles, and making all forklifts electric. Company cars at Joseph Ash Galvanizing have made the shift to electric, too. Lastly, electricity comes from renewable sources, both on-site (from solar PV arrays) and externally (by using a renewable tariff with our supplier).

All companies – regardless of industry – also need to ensure they work with companies that share their sustainability goals. All suppliers of Joseph Ash Galvanizing are vetted to include environmental accreditations and carbon reduction plans. We, in turn, are accredited to Environmental Management ISO14001 Standards.

Galvanizing’s sustainable future

Through energy efficiency, reduced emissions, resource conservation, waste minimisation, and collaboration, the galvanizing industry has paved the way for sustainability in the metals sector. The galvanizing industry’s modernisation demonstrates that even the most established practices can adapt to support a sustainable future.

- We’ll collect and deliver your steel to our site ✔️

- Comprehensive technical support, guidance and assistance at every stage ✔️

- Fast turnaround times ✔️

- Hot dip galvanized to BS EN ISO 1461 standards ✔️

- Part of a circular economy ✔️