Galvanized steel in extreme temperatures

Can galvanized steel survive extreme temperatures?

Galvanizing is a popular method of protecting steel against corrosion. But is galvanized steel resistant to extreme temperature environments, such as extreme heat or cold? Read on to learn about what temperature environments galvanized steel is suitable for.

Galvanized steel in high temperatures

Galvanizing is a long-lasting method of protecting steel against corrosion. It involves dipping steel into a bath of molten zinc, which creates a metallurgical reaction that protects the underlying metal.

The steel industry has generally recommended the service temperature for conventional coatings to be less than 200°C (390°F).

200°C is very high – much hotter than most environments – so it is unlikely that your steel fabrications will be affected by heat.

It is important to be aware that at temperatures above 200°C (390°F), you may experience peeling and changes in mechanical properties.

What is peeling?

Peeling is caused by metallurgical changes in the steel, creating a series of closely-spaced “voids” at the free zinc-alloy interface. They are produced from the diffusion of zinc from the outer free zinc layer into the inner alloy layer, caused by a difference in diffusion rates between them.

These voids expand and form a gap, causing the outer free zinc layer to split-off from the underlying zinc-iron alloy layers. This process is known as the Kirkendall Effect.

However, the remaining zinc-iron alloy layers will still provide corrosion protection for many years. How long these protective qualities last depends on the remaining coating’s thickness. At temperatures between 200°C (390°F) and 250°C (480°F) the zinc-iron alloy layers will continue to protect the steel from corrosion.

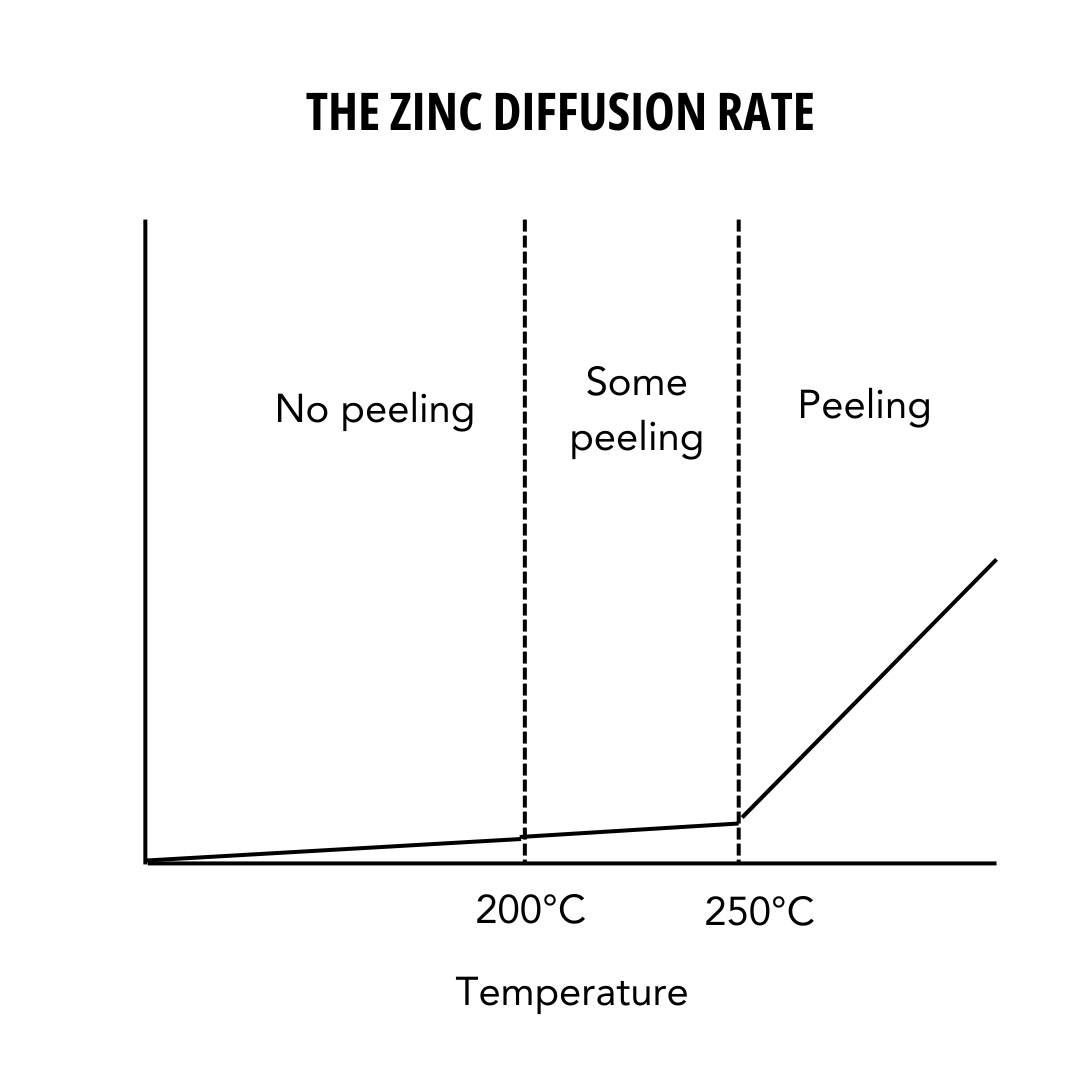

Temperatures above 250°C (480°F) will speed up the peeling process, and continued exposure can result in the zinc-iron alloy layers cracking and separating from the steel. Figure 1 shows the peeling of galvanized steel versus the temperature of the environment. For temperatures of 200°C or below, the coating resists zinc layer peeling, making hot dip galvanizing a suitable choice for these circumstances. Brief temperatures exposure up to 300°C may result in no damage to the coating.

Variables that influence steel deterioration rate

Apart from time and temperature, the rate of the deterioration process is influenced by coating thickness, the relative thickness of outer zinc and zinc-iron alloy, and by the uniformity of the individual layers. Any of the coating’s factors can affect the speed and degree of deterioration because of the effect on the length of the zinc diffusion path, or the rate of the iron-zinc interdiffusion reaction.

Peeling occurs at temperatures above 200°C, and the amount is dependent on the rise in temperature and the duration exposed. However, peeling does not mean corrosion protection is lost. During peeling, only the outer free zinc layer becomes detached, leaving the zinc-iron alloy layers to provide corrosion protection to the steel.

Figure 1. The Zinc Diffusion Rate

Other variables that can impact steel’s deterioration rate include moisture levels and contact with chemicals, such as pesticides.

Is galvanized steel fireproof?

Temperatures in fires can easily exceed 600°C. As galvanized steel starts to peel at above 200°C, this means that long-term exposure to fire can cause the steel to deteriorate. However, in short bursts, there is a potential for coating damage but many have found fire damage to be minimal on galvanized steel. A layer of carbon dust often coats the galvanized surface, but under this layer, the coating stays intact.

Changing mechanical properties

When heating at 400°C, exposures from two weeks up to 16 weeks produce relatively minor changes to the mechanical properties in the steel. The steel’s yield strength – the maximum stress that can be applied before deforming – is not significantly altered, but there is a decrease in tensile strength. These structural changes are insignificant and do not affect the design of steel structures.

Galvanized steel in cold temperatures

Unlike extreme heat, extreme cold appears to cause minimal change in galvanized coatings.

Sources have suggested that galvanized steel is unaffected in temperatures at -40°C (-40°F). Therefore, low temperature climates are an appropriate environment for hot dip galvanized steel.

However, as with any steel at very low temperatures, the material becomes brittle with extended use.

Takeaway

The recommended service temperature of 200°C has been a good benchmark for coating protection on galvanized steel with no free zinc peeling, meaning galvanized steel is suitable for most environments.

At temperatures ranging between 200°C (390°F) and 250°C (480°F) the zinc-iron alloy layers will continue to protect the steel from corrosion, but may result in some peeling. Brief temperatures exposure up to 300°C may result in no damage to the coating, but is not recommended for long-term exposure.

Colder service temperatures cause minimal change to the coating, meaning galvanized steel is ideal for these environments.

Galvanizing services in the UK

No matter your sector or size, we’re here for your galvanizing requirements. We have nine UK sites who are ready to hear from you.

- We’ll collect and deliver your steel to our site ✔️

- Comprehensive technical support, guidance and assistance at every stage ✔️

- Hot dip galvanized to BS EN ISO 1461 standards ✔️

- Part of a circular economy ✔️