What do I need to do before galvanizing?

If you’ve decided to have your steel hot dip galvanized to protect it from corrosion, you may be wondering if you need to do anything before you send it to be coated.

Whilst your galvanizer will take care of the galvanizing process for you, there are some things you must do before the galvanizer collects your steel. In this blog, we cover some pre-galvanizing preparation steps before you send your steel off to ensure a safe, quick, and effective process.

Design right for galvanizing

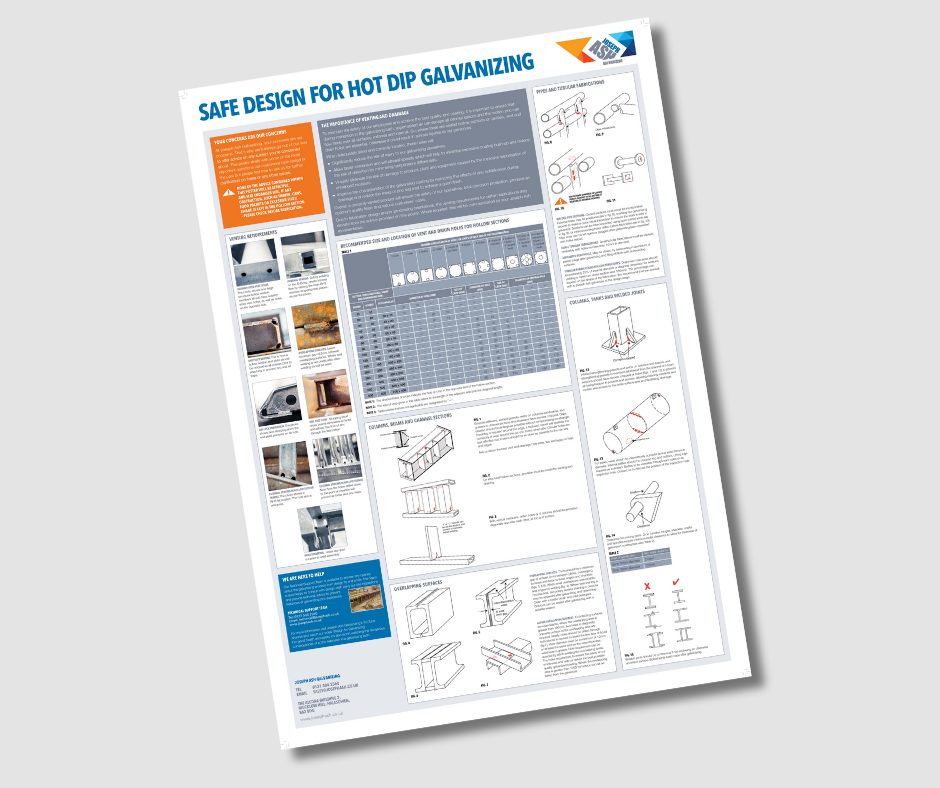

An important requirement for hot dip galvanizing is to make sure the steel has been correctly designed for the process. This includes adding ventilation holes into your steel, to make sure the molten zinc can flow freely over all internal and external surfaces and can fully drain. Otherwise, trapped air or process chemicals could cause a reaction, leading to zinc explosion. We have created a series of YouTube videos which detail what can happen if steel is not designed for galvanizing, including examples with various fabrication types

Correct design is important for keep our operatives safe and ensuring your steel is returned to you without damage. Fortunately, we’re here to help you make sure your steel is right before galvanizing. The Safe Design for Hot Dip Galvanizing flyer can be downloaded to help you better understand the technical requirements when it comes to creating vent holes in your steel. Alternatively, contact your galvanizer if you need any more assistance with venting.

Check the bath dimensions

The steel will also need to be able to fit into the galvanizing bath. This should not be a problem for many fabrications; however, it is important to check the bath sizes and dipping capabilities of your galvanizer to know what can and can’t be dipped. Double dipping is usually possible, meaning that sizes larger than the bath dimensions could be coated.

If you’re struggling for suitable locations, Joseph Ash Galvanizing is home to the widest (Telford) and deepest (Bilston) baths in the UK, suitable for dipping your large steel fabrications. Joseph Ash Chesterfield is also among one of the longest baths at over 16 metres.

For smaller steel pieces, a process known as spin galvanizing will need to be used. It follows the same fundamental process at hot dip galvanizing, except the steel will need to be placed into a perforated basket first to submerge it in the bath without losing any pieces. It is then “centrifuged”, or spun at high speeds to remove excess zinc.

Not every galvanizer caters for this process, so it is important to research into spin galvanizing providers if you need to coat small pieces such as nuts, bolts, fasteners and fixings. Joseph Ash Telford has a specialist spin galvanizing facility alongside a standard hot dip galvanizing bath.

Make sure it is clean

Ensuring the steel is free of any dirt or contaminants before it is galvanized helps the zinc adhere to the underlying steel. This helps to make the galvanizing process as effective as possible.

Contaminants could also cause a reaction with the zinc in the galvanizing bath, causing explosion from the chemicals mixing together. Articles should be free from oil, grease, paint, welding slag, lacquer, labels and glue etc. when sent for galvanizing. Shot blasting is a method of removing rust and unwanted layers from steel, helping to make the galvanizing process more effective.

Your galvanizer should check over the steel’s surface before it goes into the bath, but doing so beforehand helps reduce the amount of time the process takes. If your steel is particularly dirty, your galvanizer could refuse to accept it.

Load it safely

At Joseph Ash Galvanizing we offer a collection and delivery service, helping to save our customers time. But if you’re arranging your own transport, or are otherwise in any way involved in the delivery process, it is important to ensure you know how to stack, pack, load and secure your products for transporting them safely.

We have created our own Safe Deliveries flyer which helps customers, drivers, and our colleagues understand the importance of correct health and safety measures when delivering to and from any site.

If in doubt, ask

It’s better to ask if you’re unsure of what to do before galvanizing. If you have any questions before sending your work for galvanizing, contact your local galvanizer today.

- We’ll collect and deliver your steel to our site ✔️

- Comprehensive technical support, guidance and assistance at every stage ✔️

- Hot dip galvanized to BS EN ISO 1461 standards ✔️

- Part of a circular economy ✔️