Plant focus: Spotlight on Corby

The Joseph Ash Group takes pride in its 9 UK galvanizing plants, from Hull in the North to Medway in the South. Here, we shine the spotlight on one of our two Premier Galvanizing plants, Premier Galvanizing Corby.

Overview of Premier Galvanizing Corby

In July 2002, Premier Galvanizing opened up a second hot dip galvanizing plant based in Corby, Northamptonshire following rapid business growth.

Since then, Premier Galvanizing Corby has been a driving force in the UK steel finishing sector, developed in a region of England historically tied to the growth and development of steel and ironworks during the Industrial Revolution.

Who does Premier Galvanizing Corby serve?

We’re involved throughout the supply chain, from working with architects specifying materials through to sub-contractors and self-employed fabricators – and we can assist with technical knowledge and guidance at all stages.

Strategically located on the Willowbrook Industrial Estate, Premier Galvanizing Corby serves a vast geographical footprint, including but not limited to: London, Berkshire, Buckinghamshire, Hertfordshire, Cambridgeshire, Norfolk, Suffolk, Oxford, Derbyshire, Nottingham, Lincolnshire, and Warwickshire.

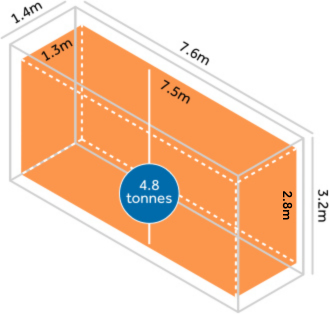

Bath size

The bath dipping size at Premier Galvanizing Corby is 7.5m (L) x 1.3m (W) x 2.8m (D), able to dip up to 4.8 tonnes. We can also double dip steel up to 13m long, accommodating for larger structures.

We can galvanize a wide range of products, from gates to 100-tonne structural steel projects.

Operating hours

Our extended opening hours mean we are open 24 hours a day, Monday to Friday, as well as weekends.

Services that go further

We’re more than a galvanizer, we’re your project partner.

As well as our core services, Premier Galvanizing Corby offers:

- Collection and delivery service: Corby operates a fleet of 4 articulated vehicles (22T) plus 8 rigid trucks (10T), ensuring fast and flexible transport options both to and from the steel’s end destination.

- Full technical support: Our specialists are on hand to advise throughout your projects, offering guidance and assistance at every stage.

- Packing and bundling: Ideal for export, containerisation, and direct-to-site delivery. This service is available on request. Certificates of conformity can also be issued upon request, and all work is conducted following BS EN ISO 1461.

- On-site storage: Convenient storage options pre- and post-galvanizing.

- Shot blasting and powder coating: Through the Joseph Ash Group, we can arrange for your work to be sent to a specialist powder coating and shot blasting service provider. We can offer your steelwork to be powder coated through an AkzoNobel Approved applicator for galvanized steel, allowing you to meet your exact specifications and requirements.

Fast turnaround options

We understand the importance of speed. That’s why Corby offers:

- 24-hour processing (by prior arrangement)

- Extended opening hours

- Overnight turnaround

High quality standards

We’re proud to hold numerous accreditations and certifications for our work and the standards we galvanize to.

All our work is fully compliant with BS EN ISO 1461 and backed by:

- ISO 45001 – Occupational Health & Safety

- ISO 9001:2015 – Quality Management

- ISO 14001:2015 – Environmental Responsibility

Your local and national partner

Whether you’re working with structural steel, architectural metalwork, or general fabrications, we’re committed to delivering the best quality steel protection. We pride ourselves on technical expertise, strong communication and a personal approach every time.

Contact Premier Galvanizing Corby to discuss your projects – we’re here to help.