Plant focus: Spotlight on Hull

The Joseph Ash Group takes immense pride in its expansive network of plants in the United Kingdom, from the northern Yorkshire region to southern county of Kent. Here, we turn our attention to our facility in Yorkshire, Premier Galvanizing Hull, to showcase its exceptional capabilities and modern amenities.

History of Premier Galvanizing Hull

Premier Galvanizing’s first site was built in Hull, East Yorkshire, back in the year 2000. Premier Galvanizing Hull proudly serviced the hot dip galvanizing needs of steel fabricators in the North East, Teesside, West Yorkshire, South Yorkshire, North Nottinghamshire, East Yorkshire and Humberside.

The development of the site came after an extensive increase in the popularity of galvanizing in Yorkshire during the 19th century. Hull experienced significant growth in the galvanizing sector thanks to its thriving maritime trade, so was vital in protecting marine steel such as anchor chains, fittings, and marine equipment. Situated on the River Humber with a bustling port, Hull became a central hub for importing and exporting goods.

Today, Premier Galvanizing Hull specialises in structural steel, architectural steel, and general fabrications.

Galvanizing services at Premier Galvanizing Hull

Whether fabricators require a small amount of steel galvanized for a sculpture or 100 tonnes for a new bridge, we can help. As well as our core hot dip galvanizing service, we offer a range of additional services.

Galvanizing bath size

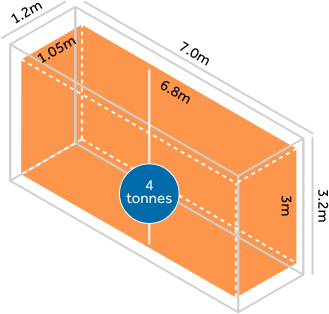

Premier Galvanizing Hull’s bath dipping size measures 7.0m x 1.2m x 3.2m, with a maximum dip weight capacity of 4 tonnes.

Double dipping is also possible for steel up to 11.5m long, enabling us to protect even larger fabrications.

Additional services

Full technical support: Our comprehensive technical support ensures customers receive guidance and assistance at every stage, guaranteeing a smooth galvanizing process.

Collection and delivery service: We can collect and deliver your steel to and from our site, saving you time. Our fleet includes two articulated vehicles capable of carrying 22 tonnes each and five rigid vehicles that can accommodate up to 10 tonnes.

Shot blasting and powder coating: These services are available through our trusted external subcontractors.

Packing and bundling: We can bundle, pack, and label your steel per your requirements and can accommodate if you need items delivered to the end user or prepared for export or containerisation.

On-site storage: Premier Galvanizing Hull allows customers to conveniently store materials before and after the galvanizing process with our on-site storage facilities.

Fast turnaround times

At Premier Galvanizing Hull, we understand the value of meeting time-sensitive demands and adhering to strict deadlines. That’s why we have extended opening hours for drop-offs and collections, and can provide expedited turnaround times including overnight or within 24 hours (by prior arrangements).

Committed to compliance

We’re proud to hold numerous accreditations and certifications for our work and the standards we galvanize to.

All our hot dip galvanizing is to BS EN ISO 1461 specifications. These standards help ensure a consistent, reliable coating is achieved from the process, with guidance on minimum specifications for coating thickness. We also hold the NQA ISO 9001:2015 accreditation for Quality Management Systems, ISO 14001:2015 for Environmental Management Systems, and ISO 45001 for Occupational Health and Safety Management Systems.

Dedicated team

From skilled shop floor operatives to transport and truck drivers, meticulous health and safety experts to the efficient administrative team, we work collaboratively to ensure that our customers receive the utmost service and see us as part of their team.

Andrew Tweddle serves as the Divisional Manager at Hull, while Chris Young oversees the Transport and Production Manager role.

To book your projects with us or for any enquiries, please don’t hesitate to contact Premier Galvanizing Hull.