Celebrating Hill & Smith’s 200 Year Anniversary

Hill & Smith PLC, Joseph Ash Galvanizing’s parent company, celebrated their incredible 200 year anniversary in June.

Founded in 1824, the group was founded by Edward Hill and was originally known as Hill’s Ironworks. Hill & Smith went on to acquire Joseph Ash Galvanizing in the year 2000, around the same time that Ash & Lacy PLC – a company founded by both Joseph Ash and John Pierce Lacy – underwent a public takeover.

To celebrate this landmark occasion, each site got to decide how they celebrated the occasion, with different events being held throughout the month of June. We’ve highlighted some of the events that took place across Joseph Ash below.

Widnes

Our Widnes Galvanising site had a retro burger van visit them, serving gourmet burgers and pancakes covered in fruit and chocolate. Their day was held on the 6th June.

Hull

Our Premier Galvanizing Hull site opted to host a fish and chip and ice cream van, with their celebrations on the 7th June. A great way to end a week!

Telford

Our Telford site opted to book a fish and chip van to the site and ordered cupcakes with Hill & Smith’s 200 Year Anniversary logo. They also held their own quiz with questions themed around the year 1824, and history about the industry and the company. There were over 30 entries in total, with prizes up for grabs including chocolates, alcohol, and a blender. Their day was held on the 24th June.

Bridgend

There were no food vans at Joseph Ash Bridgend; instead, they held a lucky dip raffle with many exciting prizes, including a 32″ TV, a 40″ oscillating fan, a deep tissue massager, alcohol and chocolate gift sets, vouchers, and even an extra day’s holiday.

They held the raffle at 6am on Monday 24th June to make sure that both day and night shifts could take part and no one missed out. Pizzas were also served throughout both the day and night. The team thoroughly enjoyed it, and it was a great way to start another week.

Congratulations to everyone who won a prize!

Chesterfield

Joseph Ash Chesterfield had an American-style burger van visit the site.

Bilston

Coming towards the end of the month, our Bilston site held a BBQ arranged by a catering company. They also had a visit from their local ice cream van. Their day was held on the 26th June.

Head Office

Finally, Head Office also celebrated on the 26th June, with a buffet breakfast arranged by Jason Anderson, Managing Director.

That’s not all though, as colleagues were also surprised with their own anniversary roses to take home for the occasion.

Joseph Ash Chesterfield has successfully met the Bronze level requirements of the Fleet Operator Recognition Scheme (FORS).

FORS is a voluntary scheme that covers all aspects of vehicle emissions, fuel efficiency, economical operations and safety.

Achieving the Bronze level means Joseph Ash Chesterfield‘s HGVs and practices meet the scheme’s requirements and the team are committed to maintaining the scheme’s standards, not just during the audit.

The Bronze audit is also the gateway to future Silver or Gold accreditations.

Well done to all involved!

Last week was sustainability week at Joseph Ash Galvanizing; a week for colleagues to focus on all things sustainability.

It can be easy to forget about sustainability when busy with day-to-day tasks, so the week serves to encourage colleagues to focus on environmental impacts and engage with the natural environment.

As part of the wider Hill & Smith PLC Group, Joseph Ash Galvanizing’s Technical department developed several activities and initiatives for the week to boost our site’s green credentials, have fun, and compete for prizes.

Take a look at some of the activities that took place across our sites below:

Biodiversity initiatives

Some of our galvanizing sites have large spaces of land surrounding them, which could be rewilded to encourage biodiversity. Managers were encouraged to let nature reclaim some of this excess land by allocating sections to be reclaimed by nature and scattering wildflower seeds to encourage new plant growth.

The new areas reclaimed by nature also serve to give colleagues a change of scenery, and potentially allow for new break areas for colleagues as we get closer to the warmer months.

Our Telford site was particularly keen to share their rewilding activities, fencing off a section of land using galvanized steel and dedicating the land enclosed to wildflower growth.

A competition to make the best birdbox was also held to further encourage biodiversity, with vouchers up for grabs for the winner.

Litter picking

Our Telford and Walsall sites have been busy taking part in some litter picking. The litter picked up can be correctly recycled instead of being left out and harming the environment.

Energy saving treasure hunt

To reduce carbon footprints at each of our sites, colleagues were encouraged to form groups and walk around the sites and and evaluate their environment, keeping sustainability in mind. This could include turning off lights, machines and other resources and questioning if they need to be used.

The energy saving treasure hunt is not a new concept; it was developed in 1999 by Toyota, and is a great activity for all companies to conduct, regardless of industry.

Competitions and prizes

There’s nothing like a bit of friendly competition, especially if it helps the environment! Prizes will be awarded for colleagues on a number of different categories:

- “Best Birdbox” award for the colleague who makes the best birdbox, with a voucher up for grabs for the winner – congratulations to Team Premier Galvanizing Corby!

- “Greatest Reduction in Energy” award for the site with the greatest reduction in CO² emissions per ton of galvanized steel for the month of May.

- “Most Sustainable Site” award for the site with the lowest year-to-date CO² output relative to galvanizing output.

Winners will be confirmed in the next few days/weeks.

Karl Hicks, Environmental and ESG Advisor at Joseph Ash, commented on the week:

“It’s been a great Sustainability Week where all the sites I’ve been to have shown real enthusiasm for getting involved, with dare I say a bit of competitive spirit. I am particularly chuffed with the fusion of “sustainability” & “galvanizing” that I’ve seen this week that demonstrates that the two are interconnected within the circular economy.

“My initial ideas for how sites could get involved have been improved on. I know that other things are in the pipeline across the sites in the next few weeks, and I’m looking forward to seeing those and dishing out awards for them accordingly.”

Overall, the week has been a huge success. Thank you and well done to all for your efforts in improving our sustainability and environmental impact!

Interested in learning more about our sustainability initiatives?

We’re approaching the Easter holidays, so to help you arrange any work required during this period, we have outlined each of our plants closing schedules below.

| Site | Closure |

| Bilston | Closed from the evening of Thursday 28th March, reopening Tuesday 2nd April 6:00am |

| Bridgend | Closed from the evening of Thursday 28th March, reopening Tuesday 2nd April |

| Chesterfield | Closed from the evening of Thursday 28th March, reopening Tuesday 2nd April |

| Corby | Closed from Thursday 28th March 9:30pm, reopening Monday 1st April 9:30pm |

| Hull | Closed from the evening of Thursday 28th March, reopening Tuesday 2nd April |

| Medway | Closed from Thursday 28th March 5:00pm, reopening Tuesday 2nd April 8:00am |

| Telford | Closed from the evening of Thursday 28th March, reopening Tuesday 2nd April |

| Walsall | Closed from the morning of Friday 29th March, reopening Tuesday 2nd April 6:00am |

| Widnes | Closed from the evening of Thursday 28th March, reopening Tuesday 2nd April |

If you have any upcoming requirements, get a quote or book a collection today to avoid disappointment.

Joseph Ash Galvanizing is delighted to announce the appointment of Jason Anderson as the Company’s new Managing Director, effective 31st January 2024.

Jason has over 20 years of Director-level experience, having previously worked as Managing Director for the Birtley Group. Jason’s experience within the Construction sector means he brings a wealth of knowledge of Joseph Ash Galvanizing’s customer base that will help drive the Company forward.

We hope you will join us in welcoming Jason to the Company.

Next pageEverything to know about our rebrand

It’s a new year, and the perfect time for us to introduce the brand-new Joseph Ash Galvanizing. Delivering the same excellent quality and service you expect, but adapted to better serve companies with their specific steel protection needs.

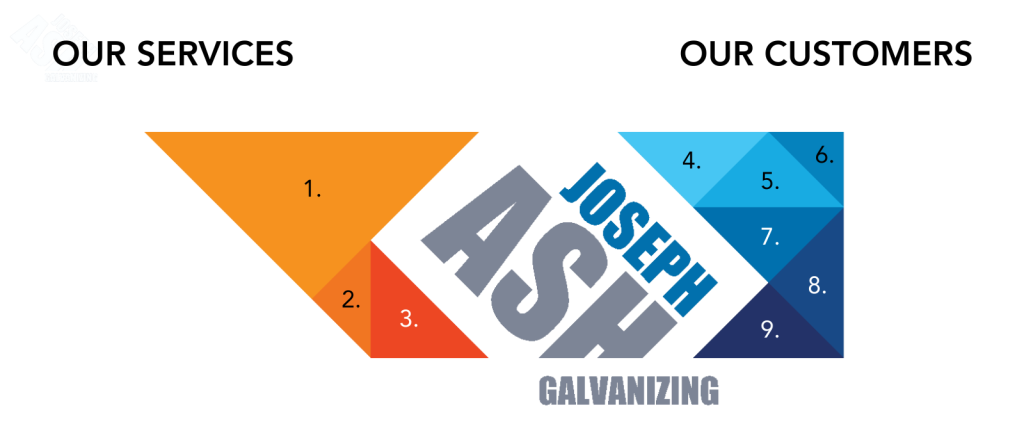

What does the new brand represent?

We’re keeping the same base logo we’ve used for many years, but restyled to better visualise and represent both our core offerings as well as the customers we aim to help.

The orange triangles represent our core services:

- 1. Hot dip galvanizing – a method of protecting steel against corrosion. We dip your steel into a bath of molten zinc, creating a durable, protective layer that can last for over a century.

- 2. Powder coating – a superior alternative to paint. Adds colour to steel and synergises with galvanizing to enhance durability and corrosion resistance.

- 3. Spin galvanizing – a method of galvanizing for protecting small fabrications, such as nuts, bolts, fasteners and fixings.

The blue triangles represent our customers’ sectors:

- 4. Transportation

- 5. Construction and Infrastructure

- 6. Nuclear and Energy

- 7. Telecoms and Data Centres

- 8. Agriculture

- 9. Sculptures

Our customers are our top priority, so representing them within our brand showcases our commitment to listening, understanding, and adapting our services to better serve specific industry demands.

What does this mean for me?

If you’re an existing customer, you can expect to receive the same excellent level of quality and service you expect from us. However, it simply means we’ll be able to deliver a more personal experience to you, and better help us communicate with you.

What if I’m not in one of the listed sectors?

The triangles represent our primary audience, but this doesn’t mean we can’t help with your steel protection requirements!

We have nine sites across the UK, offering collection and delivery services from your site to ours. We’re never too far away to protect your steel.

- We’ll collect and deliver your steel to our site ✔️

- Comprehensive technical support, guidance and assistance at every stage ✔️

- Hot dip galvanized to BS EN ISO 1461 standards ✔️

- Part of a circular economy ✔️

A huge congratulations to Pauline Alcide who recently celebrated 30 years at Joseph Ash Galvanizing!

Based at Head Office as an Assistant Accountant, Pauline has played a fundamental role within the Finance department and the wider Joseph Ash Group for many years.

Pauline commented on her time at Joseph Ash:

“I started with Joseph Ash Ltd when the company was called “Joseph Ash & Son Galvanizing Ltd“ and the head office was still in Birmingham. I was 30 years of age at the time.

“During this time, I have seen people come and go and I have also made lots of friends over the years.

“I have watched the business grow from strength to strength and worked under 4 Managing Directors who have made the company what it is today.

“I’ve thoroughly enjoyed working at Joseph Ash Ltd over the last 30 years and I am looking forward to many more years to come.”

Congratulations Pauline!

Next pageWe were proud to hold our own Oscars Awards Evening to celebrate the colleagues who played a role in helping create new internal Joseph Ash video content. The videos were created as part of a new induction process, to help introduce new starters to the company.

The evening served as a thank you to those who were closely involved in the making and filming of the videos. Their input was recognised and celebrated, with four people winning awards based on Joseph Ash Galvanizing’s values – Respect and Decency, Team Spirit, Learning and Improvement, and Taking Responsibility. Awards were presented by Stuart Whitehouse, Managing Director.

The winners were:

Respect and Decency: Osmond Crosdale

Osmond pulled together a meaningful summary of what he felt Respect and Decency looks like in Joseph Ash and went on camera to talk about this in the film. He also had his own “mic drop” moment with the final line of his summary:

“So if you have respect and you’re decent, welcome to Joseph Ash, we need you”.

Team Spirit: Estera Bak

Estera helped massively in ensuring that the Health and Safety element of our Induction video was accurate and covered everything we needed. She then travelled over from Telford to Walsall for just 15 minutes of filming for the Respect and Decency section of the video.

Learning and Improvement: Prakash Patel

Prakash was asked to do some acting during a segment of one of the films. He displayed perseverance despite needing a few takes, and progressively got more comfortable with the role. He won the Learning and Improvement award for his development and dedication during the filming process.

Taking Responsibility: Mick Barber

Mick was fundamental to the creation of the four films. He took it on his shoulders to advise technically and operationally; to cajole colleagues into acting; to get them to move products backwards and forwards on fork lifts; to stop the jig and move it back if the shot hadn’t gone right. Mick assumed responsibility from the start and demonstrated the kind of leadership that should stand as a model for our business.

Congratulations to those who won an award, and thank you to everybody involved in the creation of the videos!

Christmas is fast approaching, which means our sites will soon be shutting for the holidays.

To help you stay prepared, we’ve listed below the dates and times that our sites will be shutting, as well as the dates and times that our sites will be reopening in the new year.

Please note that while our Chesterfield site officially closes on the 21st December, the last day for galvanizing is Monday 18th December due to a bath changeover.

| Site | Schedule |

| Bilston | Close: Wednesday 20th December 2023, 12:00pm Open: Tuesday 2nd January 2024, 6:00am |

| Bridgend | Close: Friday 22nd December 2023, 6:00am Open: Tuesday 2nd January 2024. 6:00am |

| Chesterfield | Close: Thursday 21st December 2023 Open: Tuesday 2nd January 2024 NB. Last day for hot dip galvanizing is Monday 18th December due to a bath changeover. |

| Corby | Close: Thursday 21st December 2023, 4:30pm Open: Tuesday 2nd January 2024, 7:00am |

| Hull | Close: Friday 22nd December 2023, 1:00pm Open: Tuesday 2nd January 2024 |

| Medway | Close: Friday 22nd December 2023, 2:00pm Open: Tuesday 2nd January 2024, 8:00am |

| Telford | Close: Friday 22nd December 2023, 12:00pm Open: Tuesday 2nd January 2024 NB. Last day for spin galvanizing is Tuesday 19th December due to a bath pump out. |

| Walsall | Close: Tuesday 19th December 2023, 4:30pm Open: Tuesday 2nd January 2024, 8:00am |

| Widnes | Close: Friday 22nd December 2023, 12:00pm Open: Tuesday 2nd January 2024, 8:30am |

If you have any steel that needs coating before the new year, book a collection or get a quote from us today to avoid disappointment.

Widnes Galvanising, the latest addition to the Joseph Ash Group, has just launched their new environmentally-friendly passivation process!

An alternative to hexavalent chrome passivation, Widnes Galvanising’s non-chrome 6 passivation is a fantastic step towards keeping the galvanizing process environmentally friendly, as well as making sure we deliver only the best quality finish for our customers.

What is passivation?

After hot dip galvanizing has taken place, items (on request) are “passivated”. Passivation causes a chemical reaction to occur, where a thin transparent layer of metal oxide coats the galvanized steel to help reduce the effects of wet storage stain and cool the items so they can be handled safely.

Our new passivation process does not use hexavalent chromium (Cr(VI)) compounds within the process. Instead, it relies on compounds which are considered less toxic and more environmentally friendly. Our new method of passivating is a safer alternative to traditional Cr(VI) passivation, while delivering only the highest-quality finish for our customers.

Benefits of non-chrome 6 passivation

The main difference between hexavalent chrome passivation and our new non-chrome 6 passivation is its environmental impact; Widnes Galvanising’s passivation process is more environmentally-friendly than traditional Cr(VI) passivation. At Joseph Ash we’re dedicated to protecting the environment, so this is a fantastic change for our Widnes site.

Other benefits of passivation include:

- Increased corrosion resistance: Passivation significantly improves the corrosion resistance of zinc-coated steel. This is particularly important in outdoor and industrial environments where exposure to moisture, chemicals, and pollutants is common.

- Aesthetic appeal: Passivation can enhance the appearance of the galvanized surface by providing a smoother and more aesthetically pleasing finish.

- Extended lifespan: Galvanized products with passivation tend to have a longer service life, reducing maintenance and replacement costs.

- Improved adhesion: Passivation can improve the adhesion of paints and coatings to the galvanized surface, making it easier to apply and more durable.

Contact Widnes Galvanising today to discuss your hot dip galvanizing and passivation requirements.

Next page