Outdoor classroom for Solihull primary school

The first week of June marks Sustainability Week across Joseph Ash Galvanizing and Premier Galvanizing, part of the Hill & Smith PLC Group. The week aims to encourage colleagues to focus on all things sustainability, with various activities set across the week to help both the business’ sustainability and promote awareness both internally and externally.

For this year, our Premier Galvanizing Corby site was proud to donate 15 pallets to Monkspath Junior and Infant School in Solihull for the team at Hill & Smith to transform into small dens, houses, and shelving units. With summer fast approaching, it was the perfect time to create the classroom, ready for the new school term.

The classroom also incorporated painted pots, stones, tables and pinecones, alongside other elements to decorate the outdoor classroom and make the space both functional and fun.

Well done to the Hill & Smith team on the fantastic job!

Joseph Ash Chesterfield has successfully met the Bronze level requirements of the Fleet Operator Recognition Scheme (FORS).

FORS is a voluntary scheme that covers all aspects of vehicle emissions, fuel efficiency, economical operations and safety.

Achieving the Bronze level means Joseph Ash Chesterfield‘s HGVs and practices meet the scheme’s requirements and the team are committed to maintaining the scheme’s standards, not just during the audit.

The Bronze audit is also the gateway to future Silver or Gold accreditations.

Well done to all involved!

Widnes Galvanising, also known as Joseph Ash Widnes, is one of our 9 UK galvanizing plants strategically positioned across the UK. We provide insights into our services, cutting-edge facilities, and dedicated team members who tirelessly cater to our valued customers.

Joseph Ash Widnes location and history

Joseph Ash Widnes was acquired by Joseph Ash Galvanizing in October 2022, making it the recent addition to the Joseph Ash Group.

Joseph Ash Widnes is situated on the Fairway Trading Park in Cheshire. It services clients from various areas, including (but not limited to) Lancashire, Greater Manchester, Cheshire and Merseyside.

Widnes has a rich industrial history, and galvanizing has played a significant role in the region’s development. During the 19th and 20th centuries, Widnes was a major centre for the chemical industry, particularly the production of alkalis, such as soda ash and soap. The development of the chemical industry led to increased demand for materials and applications (including construction, transportation, and agriculture) that could withstand corrosion, and galvanized steel emerged as a popular choice for this purpose.

Over time, as industries evolved and the demand for galvanized products persisted, the galvanizing sector in Widnes and Cheshire continued to thrive. Today, the historical legacy of galvanizing is part of the broader industrial heritage of Widnes and its surroundings.

Galvanizing in the North West

At Joseph Ash Widnes, our expert team specialises in galvanizing a diverse range of steel products. From structural steel to street furniture, bollards, gates, railings, and balustrades – we ensure robust protection against corrosion for all.

We also take pride in delivering convenience with our comprehensive additional services, including a seamless collection and delivery service, full technical support, on-site storage facilities, and passivation post-hot dip galvanizing.

Bath size

The bath size at Joseph Ash Widnes is 6m long by 1m wide by 2.3m deep, with double dipping available. Bigger fabrications can be transported to other Joseph Ash plants with larger capacity baths, using Widnes’s fleet of trucks.

Fast turnaround times

We have extended opening hours for drop-offs and collections to help ensure our customers can arrange their work for a time that suits them best. Our commitment to convenience goes further with overnight and 2-hour turnaround times available by prior arrangement.

Uncompromising quality and compliance

Joseph Ash Widnes is dedicated to delivering services of the highest quality while adhering to stringent occupational health and safety, quality, and environmental management standards. You can expect an impeccable finish that aligns with BS EN ISO 1461 specifications when you protect your steel with us, and the site has also achieved the NQA ISO 9001:2015 accreditation for Quality Management Systems.

The Joseph Ash Group has nine plants across the UK, from Medway in the South to Hull in the North. This month, we’re shining the spotlight on Walsall to share its history and capabilities.

History of galvanizing and Joseph Ash in Walsall

Galvanizing has a rich history in Walsall, dating back to the 18th century when the town was a thriving hub of metalworking and manufacturing. With a wealth of iron and steel production facilities, the need for corrosion protection became increasingly important.

As the Industrial Revolution took hold in the late 18th century, Walsall’s metalworking industry saw significant growth – especially in the production of saddlery and harness equipment, catering to the needs of the equestrian industry.

The mid-19th century witnessed the expansion of railways, driving an escalating need for galvanized metalwork. Rails, fasteners, and signalling equipment became indispensable components of this burgeoning transportation network.

Then came the World Wars, during which Walsall’s metalworkers pivoted to producing military equipment and components crucial for the war effort.

In the latter half of the 20th century and into the 21st century, the galvanizing industry in Walsall faced economic challenges due to global competition and changes in manufacturing processes. However, companies like Joseph Ash adapted to these challenges by diversifying services and modernising facilities.

Joseph Ash Walsall overview

Joseph Ash Walsall’s clientele extends across the West Midlands, encompassing areas like West Bromwich, Warwickshire, Worcestershire, Gloucestershire, Avon, Oxfordshire, Buckinghamshire, Northamptonshire, Leicestershire, Staffordshire, Herefordshire, and Shropshire.

In addition to galvanizing, Joseph Ash Walsall offers shot blasting through an external shot-blasting subcontractor. As part of the Joseph Ash network, we also provide powder coating, duplex coatings, and spin galvanizing.

Our services are complemented by a convenient collection and delivery system, comprehensive technical support, on-site storage facilities, and passivation post hot dip galvanizing, ensuring a seamless experience for our valued clients.

Bath size

Our bath dipping size at Joseph Ash Walsall is 7.3m x 1.3m x 2.5m, and we can dip 2.5 tonnes. We can also deliver your work to other Joseph Ash sites that have different bath sizes, covering an even wider range of fabrication sizes.

Collections, deliveries, and quick turnaround times

Joseph Ash Walsall has extended opening hours to assist customers wishing to drop work off early and collect it late. Get in touch with us to find out more.

We can also provide a quick turnaround (overnight and within 24 hours) by prior arrangement.

Quality and accreditations

We’re proud to hold numerous accreditations and certifications for our work and the standards we galvanize to.

All our hot dip galvanizing is to BS EN ISO 1461 specifications. These standards help ensure a consistent, reliable coating is achieved from the process, with guidance on minimum specifications for coating thickness. We also hold the NQA ISO 9001:2015 accreditation for Quality Management Systems, ISO 14001:2015 for Environmental Management Systems, and ISO 45001 for Occupational Health and Safety Management Systems.

Here to help

Our plant is staffed by a diverse team spanning various roles, including shop floor operations, skilled transport and truck drivers, health and safety professionals, and our proficient administrative staff. We’re ready to provide the expertise and support you need.

Contact our Walsall team today to book a collection or get a quote.

Widnes Galvanising, the latest addition to the Joseph Ash Group, is developing their new environmentally-friendly passivation process!

An alternative to hexavalent chrome passivation, Widnes Galvanising Ltd’s (also known as Joseph Ash Widnes) non-chrome 6 passivation is a fantastic step towards keeping the galvanizing process environmentally friendly, as well as making sure we deliver only the best quality finish for our customers.

What is passivation?

After hot dip galvanizing has taken place, items (on request) are “passivated”. Passivation causes a chemical reaction to occur, where a thin transparent layer of metal oxide coats the galvanized steel to help reduce the effects of wet storage stain and cool the items so they can be handled safely.

Our new passivation process does not use hexavalent chromium (Cr(VI)) compounds within the process. Instead, it relies on compounds which are considered less toxic and more environmentally friendly. Our new method of passivating is a safer alternative to traditional Cr(VI) passivation, while delivering only the highest-quality finish for our customers.

Benefits of non-chrome 6 passivation

The main difference between hexavalent chrome passivation and our new non-chrome 6 passivation is its environmental impact; Joseph Ash Widnes’ passivation process is more environmentally-friendly than traditional Cr(VI) passivation. At Joseph Ash we’re dedicated to protecting the environment, so this is a fantastic development for our Widnes site.

Other benefits of passivation include:

- Increased corrosion resistance: Passivation significantly improves the corrosion resistance of zinc-coated steel. This is particularly important in outdoor and industrial environments where exposure to moisture, chemicals, and pollutants is common.

- Aesthetic appeal: Passivation can enhance the appearance of the galvanized surface by providing a smoother and more aesthetically pleasing finish.

- Extended lifespan: Galvanized products with passivation tend to have a longer service life, reducing maintenance and replacement costs.

- Improved adhesion: Passivation can improve the adhesion of paints and coatings to the galvanized surface, making it easier to apply and more durable.

Contact Widnes Galvanising today to discuss your hot dip galvanizing and passivation requirements.

The Joseph Ash Group is home to 9 UK galvanizing sites; here, we spotlight Joseph Ash Medway, our North West galvanizing plant in Kent.

Joseph Ash Medway location

Joseph Ash Medway is located within the Eurolink Industrial Centre in Sittingbourne. With an extensive fleet of vehicles, we cater to galvanizing needs in Kent, London, Essex, East Sussex, West Sussex, Surrey, Hertfordshire, Buckinghamshire, Berkshire, Hampshire, Bedfordshire, Cambridgeshire, Suffolk, Norfolk and Wiltshire.

Galvanizing at Joseph Ash Medway

Joseph Ash Medway’s bath dipping size measures 6.5m x 1.2m x 2.2m, with a maximum dip weight capacity of 2.6 tonnes.

Whether you require a galvanized finish for a garden gate, or 300 metres of powder coated railings for local waterfronts, Joseph Ash Medway can help.

More than galvanizing

Joseph Ash Medway offers more than hot dip galvanizing; the site is a one stop shop facility for shot blasting, hot dip galvanizing, and powder coating.

Powder coating

We can offer a wide range of colours and textures for your steel, from metallic to textured, as well as varying matt, satin, and gloss levels.

We can also powder coat raw steel and aluminium, providing enhanced corrosion protection and longevity compared to traditional liquid paint, while still being available in any colour to suit your specifications.

Joseph Ash Medway is an AkzoNobel Approved applicator for galvanized steel, one of only a handful of companies with this status. We’re trusted to deliver AkzoNobel’s Interpon range of powder coating colours, so your steel will be powder coated to the highest quality and to your project specifications.

What is a duplex coating?

When hot dip galvanizing and powder coating is used on the same steel fabrication, it is known as a duplex coating. This is particularly popular across the balcony, balustrade and street furniture sectors, where protection against the elements – combined with the ability to stand out or blend in – is key.

Joseph Ash Medway offers a 25-year guarantee on duplex coatings (subject to T&Cs).

Additional services

In addition to core services, Joseph Ash Medway offers:

- Collection and delivery service

- Full technical support

- Packing and bundling

- On-site storage

Mono Hinge Self Closing Gate®️

Our Joseph Ash Medway site is also home to the Mono Hinge Self Closing Gate®️ – the trusted safety play gate designed for children’s play areas. The Mono Hinge Gates are completely free of finger traps, head traps, foot traps, crush points, shear actions and sharp edges. They are also DDA-compliant and vandal-resistant, proving a popular choice for businesses and local authorities.

Our accreditations

We’re proud to hold numerous accreditations and certifications for our work and the standards we galvanize to.

All our hot dip galvanizing is to BS EN ISO 1461 specifications. These standards help ensure a consistent, reliable coating is achieved from the process, with guidance on minimum specifications for coating thickness. We also hold the NQA ISO 9001:2015 accreditation for Quality Management Systems, ISO 14001:2015 for Environmental Management Systems, and ISO 45001 for Occupational Health and Safety Management Systems. The site also holds certifications in BS EN 13438 and BS EN 15773.

In addition to being AkzoNobel Approved, Joseph Ash Medway is JOSCAR registered, confirming our services meet the standards required for businesses in the Aerospace, Defence and Security services.

Our team at Medway

The Medway team encompasses dedicated individuals who know their roles inside out. They provide a top-notch steel protection service, where your needs are their priority.

Richard Colegate is the Divisional Manager at Medway. Daniel Lyons, Rebekah Skipper, and Michelle Newell manage sales and customer service advisory.

The Joseph Ash Group takes immense pride in its expansive network of plants in the United Kingdom, from the northern Yorkshire region to southern county of Kent. Here, we turn our attention to our facility in Yorkshire, Premier Galvanizing Hull, to showcase its exceptional capabilities and modern amenities.

History of Premier Galvanizing Hull

Premier Galvanizing’s first site was built in Hull, East Yorkshire, back in the year 2000. Premier Galvanizing Hull proudly serviced the hot dip galvanizing needs of steel fabricators in the North East, Teesside, West Yorkshire, South Yorkshire, North Nottinghamshire, East Yorkshire and Humberside.

The development of the site came after an extensive increase in the popularity of galvanizing in Yorkshire during the 19th century. Hull experienced significant growth in the galvanizing sector thanks to its thriving maritime trade, so was vital in protecting marine steel such as anchor chains, fittings, and marine equipment. Situated on the River Humber with a bustling port, Hull became a central hub for importing and exporting goods.

Today, Premier Galvanizing Hull specialises in structural steel, architectural steel, and general fabrications.

Galvanizing services at Premier Galvanizing Hull

Whether fabricators require a small amount of steel galvanized for a sculpture or 100 tonnes for a new bridge, we can help. As well as our core hot dip galvanizing service, we offer a range of additional services.

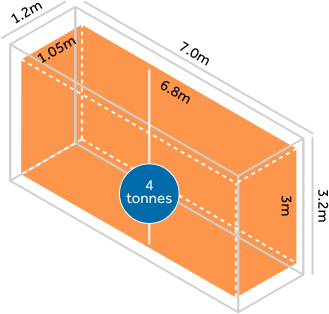

Galvanizing bath size

Premier Galvanizing Hull’s bath dipping size measures 7.0m x 1.2m x 3.2m, with a maximum dip weight capacity of 4 tonnes.

Double dipping is also possible for steel up to 11.5m long, enabling us to protect even larger fabrications.

Additional services

Full technical support: Our comprehensive technical support ensures customers receive guidance and assistance at every stage, guaranteeing a smooth galvanizing process.

Collection and delivery service: We can collect and deliver your steel to and from our site, saving you time. Our fleet includes two articulated vehicles capable of carrying 22 tonnes each and five rigid vehicles that can accommodate up to 10 tonnes.

Shot blasting and powder coating: These services are available through our trusted external subcontractors.

Packing and bundling: We can bundle, pack, and label your steel per your requirements and can accommodate if you need items delivered to the end user or prepared for export or containerisation.

On-site storage: Premier Galvanizing Hull allows customers to conveniently store materials before and after the galvanizing process with our on-site storage facilities.

Fast turnaround times

At Premier Galvanizing Hull, we understand the value of meeting time-sensitive demands and adhering to strict deadlines. That’s why we have extended opening hours for drop-offs and collections, and can provide expedited turnaround times including overnight or within 24 hours (by prior arrangements).

Committed to compliance

We’re proud to hold numerous accreditations and certifications for our work and the standards we galvanize to.

All our hot dip galvanizing is to BS EN ISO 1461 specifications. These standards help ensure a consistent, reliable coating is achieved from the process, with guidance on minimum specifications for coating thickness. We also hold the NQA ISO 9001:2015 accreditation for Quality Management Systems, ISO 14001:2015 for Environmental Management Systems, and ISO 45001 for Occupational Health and Safety Management Systems.

Dedicated team

From skilled shop floor operatives to transport and truck drivers, meticulous health and safety experts to the efficient administrative team, we work collaboratively to ensure that our customers receive the utmost service and see us as part of their team.

Andrew Tweddle serves as the Divisional Manager at Hull, while Chris Young oversees the Transport and Production Manager role.

To book your projects with us or for any enquiries, please don’t hesitate to contact Premier Galvanizing Hull.

The Joseph Ash Group takes pride in its 9 UK galvanizing plants, from Hull in the North to Medway in the South. Here, we shine the spotlight on one of our two Premier Galvanizing plants, Premier Galvanizing Corby.

Overview of Premier Galvanizing Corby

In July 2002, Premier Galvanizing opened up a second plant based in Corby, Northamptonshire following rapid business growth. Premier Galvanizing Corby is in a region of England historically tied to the growth and development of steel and ironworks during the Industrial Revolution. Corby was once best known for its iron and steel industry, which shaped the growth of the town and influenced all aspects of life, from the turn of the 20th century until the closure of the steelworks in the 1980s.

Premier Galvanizing Corby location

Premier Galvanizing Corby is located on the Willowbrook Industrial Estate. With its extensive fleet of vehicles, it covers customers’ galvanizing requirements across the Midlands as well as London, Berkshire, Buckinghamshire, Hertfordshire, Cambridgeshire, Norfolk, Suffolk, Oxford, Derbyshire, Nottingham, Lincolnshire, and Warwickshire.

What is galvanized at Premier Galvanizing Corby?

The main classes of work that are galvanized at Premier Galvanizing Corby are structural steel, architectural steel, and general fabrications. Whether you need a small amount of steel galvanized for a gate or 100 tonnes of steel for a new building development, Premier Galvanizing Corby can help.

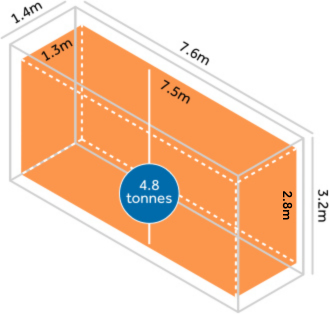

Bath size

The bath dipping size at Premier Galvanizing Corby is 7.5m x 1.3m x 2.8m, able to dip up to 4.8 tonnes.

Double dipping is also possible for steel up to 13m long, accommodating for larger structures.

Additional services

As well as core services, Premier Galvanizing Corby offers various additional services to simplify the process.

- Collection and delivery service: Wherever you are or wherever the end destination for your fabrications is, Premier Galvanizing can collect and deliver it to and from its end destination. Corby operates a fleet of 4 articulated vehicles capable of carrying 22 tonnes each, plus 8 rigids that can carry up to 10 tonnes.

- Full technical support: Providing customers with comprehensive technical support, offering guidance and assistance at every stage.

- Packing and bundling: Bundling, packing, and labelling of steel is possible on request. Just let us know your requirements, especially if you want us to deliver your items to the end user or prepare them for export or containerisation. Certificates of conformity can be issued upon request, and all work is conducted following BS EN ISO 1461.

- On-site storage: Premier Galvanizing Corby offers ample on-site storage capacity, allowing you to store materials conveniently before and after galvanizing.

- Shot blasting and powder coating: Through the Joseph Ash Group, we can arrange for your work to be sent to our specialist powder coating and shot blasting facility at Joseph Ash Medway, offering all three services in one location. The site is an AkzoNobel Approved powder coating applicator for galvanized steel, allowing you to meet your exact specifications and requirements.

Fast turnaround times

We have extended opening hours for drop-offs and collections and offer expedited turnaround times, including overnight and within 24 hours, with prior arrangement. We aim to make the process as seamless as possible so your project is completed without delay.

Our high standards

We’re proud to hold numerous accreditations and certifications for our work and the standards we galvanize to.

All our hot dip galvanizing is to BS EN ISO 1461 specifications. These standards help ensure a consistent, reliable coating is achieved from the process, with guidance on minimum specifications for coating thickness. We also hold the NQA ISO 9001:2015 accreditation for Quality Management Systems, ISO 14001:2015 for Environmental Management Systems, and ISO 45001 for Occupational Health and Safety Management Systems.

Our people

From skilled shop floor operatives to transport and truck drivers, meticulous health and safety experts to the efficient administrative team, we aim to be part of your team.

Contact Premier Galvanizing Corby to discuss your projects.

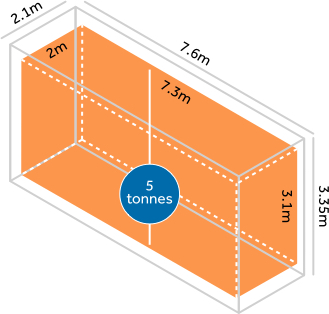

Looking for the widest galvanizing bath in the UK? Look no further than Joseph Ash Telford!

When it comes to looking for the perfect galvanizing service provider, bath size matters. The right size galvanizing bath will ensure your steel fabrications are evenly and sufficiently coated in zinc.

At two meters wide, the UK’s widest galvanizing bath can handle bigger and more complex projects than our competitors. Joseph Ash Telford is the ideal place to galvanize your fencing, structural steel, trailers, sculptures, or any other wide metal fabrications.

Why a wider galvanizing bath is better

There are numerous reasons why the width of our Telford bath makes it the ideal place to hot dip galvanize your metal fabrications.

Increased Capacity: A wider galvanizing bath can handle larger and more complex items. This allows you to protect bigger projects without needing to downsize them, saving you time and money. We can also process more of your items at once, reducing the overall turnaround time for projects. This allows us to meet tighter deadlines so you get your projects back quicker.

Reduced Handling: With a wider bath, you can process larger items without needing to handle them as much. Less handling reduces the risk of damage to the items and increases the efficiency of the handling process.

Better Coating Quality: A wider bath allows the molten zinc to flow more freely over all surfaces, both internal and external, of the metal. This ensures consistency with the coating’s thickness and quality. This is particularly important for complex items, where getting complete coverage on all surfaces can be difficult.

Cost Savings: By being able to process larger items in a single bath, we can save you money on energy, labour, and maintenance, helping you reduce your expenses overall.

The bath’s dipping dimensions are also 7.3 meters long and 3.1 meters deep, with a volume capacity of 5 tonnes. These dimensions make it capable of containing almost any large metal fabrication.

Contact our Telford site today to get a quote on your wide steel fabrications.

The Joseph Ash Group is home to 9 UK galvanizing plants, ranging from Medway in the South to Hull in the North. Here, we shine the spotlight on our Joseph Ash Chesterfield site, our Fit4Nuclear accredited galvanizing plant in the Midlands.

About Joseph Ash Chesterfield

Joseph Ash Chesterfield is located just half a mile off the M1 Junction 29 at Holmewood Industrial Estate, making it conveniently location for those arranging their own transport. Wee can also offer collection and delivery across the Midlands with a daily milk run service within a 50-mile radius of the plant.

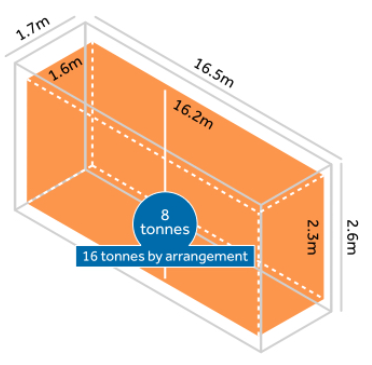

Joseph Ash Chesterfield is home to our largest galvanizing bath, at over 16 metres in length and a double-dip capacity of 18m length, able to galvanize even the largest of structural steel fabrications such as support columns.

History of galvanizing in Chesterfield

Joseph Ash Chesterfield is based in Derbyshire, a region of England historically tied to the growth and development of the steel and iron industry in the 19th century.

With so much metalwork and engineering in the area, galvanizing was essential in protecting steel and iron products from rust and corrosion, extending their lifespan, and enhancing their durability.

Accreditations

Fit for Nuclear

Joseph Ash Chesterfield is the only plant in the UK that is Fit for Nuclear (F4N) certified, demonstrating the site’s commitment to quality, safety, and compliance with nuclear industry standards. Steel components for the nuclear industry include building supports, platforms, walkways, and structural steel.

As the nuclear industry is highly specialised and safety-critical, our galvanizing must pass rigorous evaluation and qualification processes to ensure compliance with stringent standards and regulations.

FORS Gold

Joseph Ash Chesterfield is also the first galvanizing company in the UK to achieve FORS Gold accreditation for their transport fleet. The accreditation is no easy achievement, being the highest level the scheme achieves. Gold accreditation confirms our dedication to driver and vehicle safety, combined with improving operating practices through effective monitoring of fuel and tyre usage. If you’re looking for collection and delivery of your work to and from our site, you can be sure it’s arranged by a company that takes safety seriously.

Additional services

Outside of galvanizing, Joseph Ash Chesterfield also offers:

- Collection and delivery service: The site provides collections and deliveries throughout the Midlands and the North, and a daily milk run service within a 50-mile radius of the plant and the M1 corridor. The site’s dipping capabilities also mean we undertake work further away too, operating a fleet of seven articulated vehicles capable of carrying 28 tonnes each, plus five rigids which can also carry up to 15 tonnes. The fleet also has 48 trailers to maintain customers’ work.

- Full technical support: Providing customers with comprehensive technical support, offering guidance and assistance at every stage.

- On-site storage: With over 10 acres of available space, Joseph Ash Chesterfield offers ample on-site storage capacity, allowing customers to store materials conveniently before and after galvanizing.

- Trailer storage: Customers can take advantage of a designated area capable of accommodating up to 100 trailers, providing a secure space for transportation needs.

- Crane gantry area: The crane gantry area at Chesterfield features ramps and bays, enabling customers to load their containers and trailers efficiently and effortlessly under six external cranes.

- Fabrication pre-testing: Chesterfield includes a dedicated area where customers can assemble and pre-test their fabrications before taking them off-site for delivery to the end user.

- Truck driver facilities: Overnight and changing facilities are available for the comfort of truck drivers. Chesterfield also has a truck stop located directly opposite the plant.

- Forklift fleet: Chesterfield will soon be in the possession of the most up to date electric fleet of forklifts using an Opti Fleet computerised system. We have four 3.5 tonne and one 4.5 combi forklift trucks.

Bath size

The bath dipping size at Joseph Ash Chesterfield is 16.2m x 1.6m x 2.3m, and the team can dip 8 tonnes (or 16 tonnes by arrangement). Double dipping can also be undertaken (height and length).

The dimensions make it suitable for even the largest of steel fabrications.

Extended opening times

To help provide speedy turnarounds, the plant has extended opening hours for drop-offs and collections. Chesterfield also offers quick turnaround times (overnight and within 24 hours) by prior arrangement.

The highest standards

We’re proud to hold numerous accreditations and certifications for our work and the standards we galvanize to.

All our hot dip galvanizing is to BS EN ISO 1461 specifications. These standards help ensure a consistent, reliable coating is achieved from the process, with guidance on minimum specifications for coating thickness. We also hold the NQA ISO 9001:2015 accreditation for Quality Management Systems, ISO 14001:2015 for Environmental Management Systems, and ISO 45001 for Occupational Health and Safety Management Systems.